A fourth-party logistics provider, or 4PL, is like the master chef of the supply chain, coordinating various logistics services to create an excellent dish – an optimized supply chain.

Unlike third-party logistics (3PL) providers, which handle specific tasks such as warehousing, shipping, and order fulfillment, fourth-party logistics (4PL) providers manage and improve the entire supply chain.

Today we’ll explore fourth-party logistics, explaining its details, its key role in logistics strategies, and how it fits into the wider world of supply chain management. But let’s not get lost in the metaphor. By the end of this blog, you’ll have the answers to all your questions about 4PL logistics.

What is 4PL Logistics in the Supply Chain?

It represents a supply chain operating model where a business entrusts its logistics management entirely to an external service provider. Also known as lead logistics providers, it oversee all distribution chain activities and monitors both operational and financial efficiency within the supply chain.

Acting as a singular point of contact for transit management, this entity assumes responsibilities such as infrastructure management, resource allocation, and technology deployment essential for seamless supply chain operations.

These companies utilize advanced technology to strategize, execute, and ensure compliance throughout their client’s supply chain network.

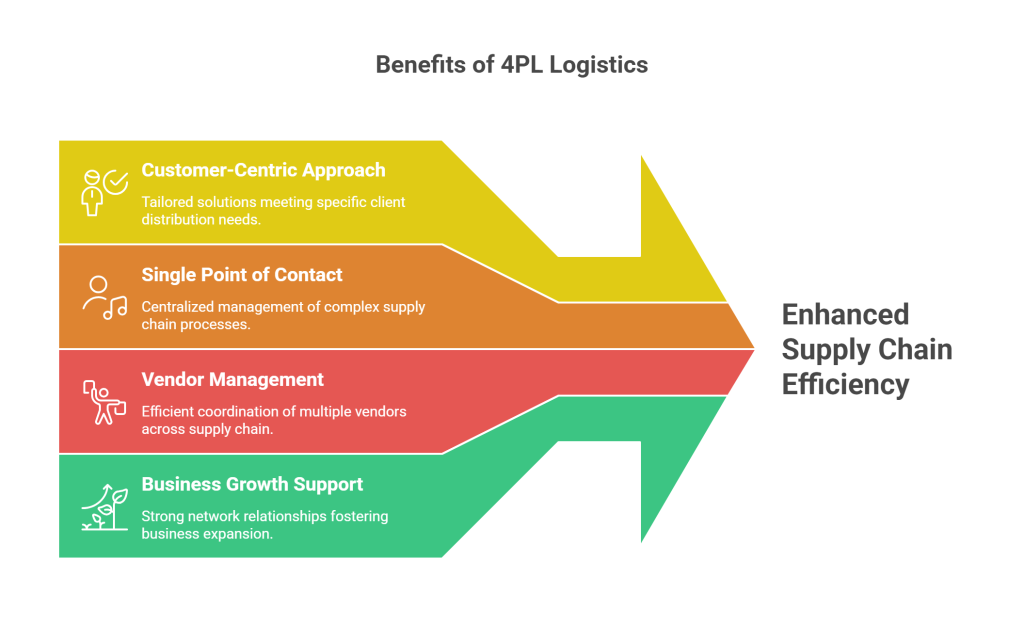

Benefits of 4PL Logistics

Such companies play a crucial role in the supply chain, assuming broader responsibilities compared to 3PL firms and offering deeper accountability in achieving businesses’ strategic objectives. Associating with 4PL firms provides several significant advantages:

1. Customer-Centric Approach

4PL providers tailor logistic solutions precisely to meet client specifications across the entire distribution chain. Proficient in managing comprehensive operations spanning distribution, warehousing, logistics, and IT, they ensure optimal solutions for every aspect.

2. Single Point of Contact

Acting as the sole interface between businesses and their supply chain processes, 4PL providers adeptly oversee and manage logistics complexities. They coordinate every logistical step, from material sourcing and manufacturing considerations to implementing tailored solutions, offering a holistic view of the company’s supply chain operations.

3. Management of Multiple Vendors

Handling multiple vendors across the distribution chain can be daunting for businesses, but 4PL providers streamline this challenge. They efficiently manage the vendor ecosystem, encompassing warehousing, procurement, distribution, transportation, and IT aspects of the supply chain.

4. Supporting Business Growth

By fostering strong relationships within the supply chain network, 4PL providers facilitate business growth. They leverage trusted networks to support enterprise expansion, maintaining solid partnerships with national and international stakeholders. This enables them to develop robust systems for seamless goods execution.

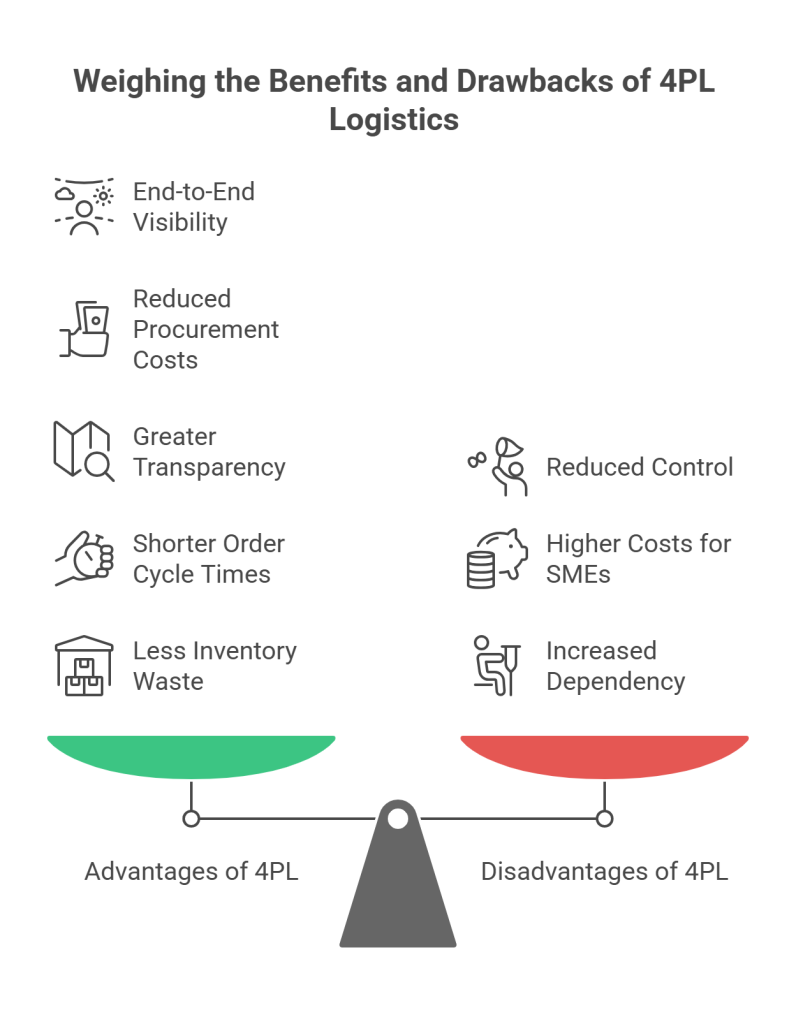

Weighing the Benefits and Drawbacks of 4PL Logistics

Advantages of 4PL Logistics in the Supply Chain

A Fourth-Party Logistics (4PL) provider goes beyond traditional logistics support. Unlike 3PL (Third-Party Logistics) companies that handle specific tasks like warehousing or transportation, a 4PL partner takes full ownership of the entire logistics operation — from strategy and planning to execution — often coordinating multiple 3PL vendors in the process.

Here are some of the key benefits of working with a 4PL provider:

1. End-to-End Supply Chain Visibility

One of the biggest advantages of a 4PL is the ability to offer a clear, real-time view of your entire supply chain. From procurement and warehousing to distribution and delivery, you get comprehensive oversight. This improved visibility helps businesses detect bottlenecks early, reduce delays, and make informed decisions faster.

2. Reduced Procurement Costs

4PL providers typically have strong networks and long-standing relationships with logistics vendors. They can leverage their buying power and market knowledge to negotiate better rates, helping businesses lower their procurement and logistics expenses significantly.

3. Greater Transparency in Market Operations

By acting as a neutral party, a 4PL partner gives you unbiased insights into supplier performance, market rates, and service quality. This increased transparency supports smarter decision-making and gives businesses a competitive edge in sourcing and vendor management.

4. Shorter Order Cycle Times

With a 4PL coordinating all moving parts — from inbound materials to last-mile delivery — order fulfillment becomes faster and more reliable. This leads to shorter order cycle times, helping businesses meet customer expectations more consistently.

5. Centralized Management of All Supply Chain Vendors

Managing multiple logistics partners can be complex and time-consuming. A 4PL provider acts as a single point of contact for all vendors, simplifying operations and improving coordination across the supply chain. This centralisation reduces administrative burden and enhances accountability.

6. Less Inventory Waste and Better Stock Control

With more accurate forecasting and efficient logistics planning, a 4PL can help reduce excess inventory and minimize wastage. This is especially valuable for industries where products have a limited shelf life or demand fluctuates often.

Disadvantages of 4PL Logistics in the Supply Chain

While 4PL logistics can offer several strategic advantages, it’s important to consider some potential downsides as well. These factors can vary based on the size of your business, the complexity of your operations, and your long-term logistics goals.

1. Reduced Control Over Logistics Operations

By handing over the reins to a 4PL provider, businesses may lose direct control over certain processes like warehousing, transportation, and fulfillment. This can be a concern for companies that prefer a hands-on approach or have very specific operational standards.

2. Increased Dependency on the 4PL Partner

Since a 4PL integrates deeply with your supply chain and oversees crucial functions, businesses can become highly dependent on them over time. If the partnership doesn’t work out or if the 4PL fails to deliver, transitioning to a new provider can be complex and disruptive.

3. Higher Costs for Small and Medium Enterprises (SMEs)

While 4PLs offer cost efficiencies in the long run, the initial investment can be high — especially for small or mid-sized businesses. The cost of engaging a 4PL may not always justify the benefits if the supply chain isn’t large or complex enough to warrant full-scale management.

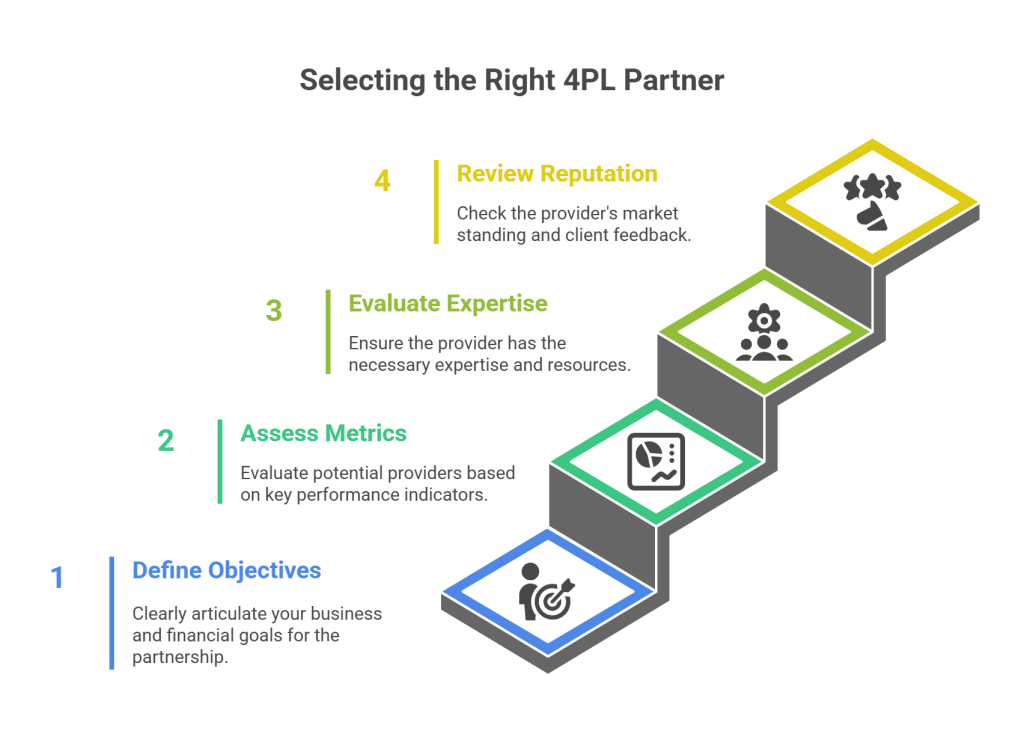

How to Choose a 4PL Logistics for the Supply Chain?

Selecting the right Fourth-Party Logistics (4PL) partner is a strategic decision that can significantly influence your supply chain performance. To make an informed and effective choice, businesses should carefully assess several critical factors. Here’s a step-by-step guide to help you evaluate and choose the most suitable 4PL provider:

1. Define Your Business and Financial Objectives

Before starting the selection process, clearly articulate what you want to achieve with a 4PL partnership.

- Identify your short-term and long-term logistics goals.

- Outline specific operational challenges you expect the 4PL provider to solve.

- Use tools such as warehouse management systems (WMS) to evaluate current pain points and improvement areas.

- Ensure your objectives are measurable, such as reducing delivery lead times, optimizing inventory, or cutting logistics costs.

2. Assess Key Operational Metrics

Evaluate potential 4PL providers based on relevant performance indicators that align with your business needs.

Key metrics to consider:

- Transportation and warehousing costs

- Geographical reach and warehouse locations

- On-time delivery performance and service-level agreements (SLAs)

- Handling capabilities (bulk, perishable, fragile, etc.)

- Scalability and adaptability of their logistics infrastructure

- Technology integration and data transparency

- Estimated return on investment (ROI)

These indicators provide a practical basis for comparing providers and predicting potential outcomes.

3. Evaluate Their Expertise and Resources

A reliable 4PL partner should offer not just logistical support but also a depth of experience and strong resource capabilities.

Assess the provider’s expertise in:

- End-to-end supply chain management

- Taxation and compliance handling across regions

- IT systems and technology integration (ERP, TMS, WMS, etc.)

- Customer support and responsiveness

- Financial stability and scalability of services

A well-rounded 4PL partner should also have access to a broad network of third-party vendors, strong data analytics capabilities, and proven frameworks for supply chain optimization.

4. Review Reputation and Client Feedback

Before finalizing a partnership, perform due diligence on the 4PL company’s market standing.

- Explore client testimonials, reviews, and case studies.

- Investigate their track record in achieving KPIs and cost reductions.

- Understand how they handle collaborative team efforts and implementation timelines.

- If possible, speak directly with past or existing clients to get first-hand feedback.

This will help you identify potential red flags and ensure you’re partnering with a provider that delivers on its promises.

The Future of 4PL Logistics in the Supply Chain Industry

The surge in e-commerce has transformed how businesses operate across the globe. Even small enterprises, once confined to regional markets, now have the tools to reach international customers with ease. This global exposure opens up vast growth opportunities—but it also presents significant logistical challenges.

1. Overcoming Distance Through Strategic Logistics

As online businesses scale, the complexities of managing deliveries over long distances become more apparent. Timely fulfilment, cost control, and customer satisfaction are often jeopardized by logistical inefficiencies. This is where Fourth-Party Logistics (4PL) providers have become game changers. By taking full control of supply chain orchestration—including coordinating with multiple 3PL partners—they are resolving pain points that e-commerce businesses frequently encounter.

2. Streamlining Fulfilment and Operational Costs

4PL providers are contributing to:

- Faster order fulfilment through optimized shipping routes and intelligent inventory placement

- Reduced operational overheads by eliminating redundancies in warehousing and transportation

- Greater supply chain efficiency, minimizing delays and manual interventions

These improvements are not just operational—they also lead to direct cost savings and improved service levels.

3. Value Beyond Efficiency

While improving shipping times and reducing costs are major wins, 4PL logistics is delivering value that goes well beyond traditional logistics goals. Companies are beginning to realize several strategic advantages:

- Enhanced customer satisfaction through timely deliveries, accurate order tracking, and improved service consistency

- Greater focus on core competencies as logistics operations are offloaded to experts

- Scalability and flexibility, which enable businesses to expand into new markets or manage seasonal fluctuations without infrastructure worries

This holistic approach empowers businesses to adapt quickly to market changes and customer expectations—key to long-term success in a digital-first economy.

Conclusion

In conclusion, 4PL logistics is a big step forward in managing how goods move from one place to another. It helps businesses a lot by making operations smoother and more efficient.

By letting experts handle logistics, companies can save money and grow better. Even though there are challenges like less control over how things get done, the benefits—like happier customers and smoother operations—make it worth it for most businesses.

As the logistics world keeps changing, new solutions like those from Qodenext make it easier for businesses to handle challenges and grow.

FAQs: Everything About 4PL Logistics in Supply Chain Management

1. How many types of 4PL logistics are there?

There are generally two types:

- Asset-light: Focuses on managing and coordinating supply chain activities without owning physical assets.

- Asset-heavy: Includes owning and managing physical assets like warehouses and transportation fleets.

2. Is 4PL better than 3PL?

It often offers more comprehensive supply chain management, including strategic oversight and integration of multiple 3PLs. It can be better for businesses needing broader logistical control and optimization.

3. Can I use 4PL in my large warehouse?

Yes, it can be utilized effectively in large warehouses. It provides strategic management of operations, including inventory management, transportation optimization, and overall coordination.

4. Who introduced the 4PL logistics?

The concept was introduced by Accenture in the late 1990s. They defined it as a higher level of management where the provider acts as a strategic partner overseeing multiple logistics service providers.

5. What are the two main types of 4PL providers?

- Asset-light 4PLs: Focus on coordination and management without owning physical assets.

- Asset-heavy 4PLs: Own warehouses, vehicles, and other logistics infrastructure in addition to providing management services.

6. Is 4PL suitable for small businesses?

Not always. 4PL services can be expensive and may only be cost-effective for larger businesses or those with complex supply chain requirements.

7. What industries benefit the most from 4PL logistics?

Industries with complex global supply chains, such as retail, automotive, pharmaceuticals, and electronics, often gain the most from 4PL partnerships.

8. How does 4PL improve supply chain visibility?

4PLs use advanced technology platforms to monitor goods in real-time, track KPIs, and generate reports that offer full visibility across every stage of the supply chain.

9. Can a 4PL provider replace an internal logistics team?

Yes, in many cases. A 4PL acts as an external logistics department, handling planning, execution, and optimization — allowing your team to focus on core business operations.