Every package you receive, every order delivered on time, and every shipment that moves seamlessly across the globe is the result of something bigger happening behind the scenes: logistics. Yet, logistics isn’t always smooth sailing. Congested routes, mismanaged inventories, and unpredictable delays are everyday realities. That’s why logistics optimization has become such a game-changer.

In this blog, we’ll walk through the world of end-to-end logistics optimization – how it works, why it matters, and the tools that make it possible. We’ll explore everything from logistics route optimization to 3PL logistics optimization, look at logistics optimization models, and break down the logistics optimization process step by step. We’ll also explore how logistics optimisation software is helping businesses stay ahead in a world that never slows down.Let’s get started.

What is Logistics Optimization?

At its core, logistics optimization refers to the use of strategies, tools, and technologies to improve the efficiency, cost-effectiveness, and reliability of logistics operations. This includes:

- Planning transportation routes.

- Managing warehouse operations.

- Tracking deliveries in real time.

- Optimizing resource usage, like trucks, labor, and fuel.

It’s essentially about doing more with less, while ensuring on-time deliveries and reducing waste.

The Need for End-to-End Logistics Optimization

Modern supply chains are complex. A single shipment may cross multiple borders, involve third-party providers, and require real-time coordination between manufacturers, warehouses, and customers. Without optimization, these complexities often lead to:

- Higher costs.

- Delivery delays.

- Inefficient use of assets.

- Poor visibility across the supply chain.

By applying end-to-end logistics optimization, companies can ensure that every step right from planning routes to final delivery, is streamlined, measurable, and customer-centric.

Planning: The Foundation of Logistics Optimization

Effective logistics always begins with strong planning. This is where companies analyze demand, capacity, and resources to design efficient systems.

Key aspects of planning include:

- Demand Forecasting: Using historical data and predictive analytics to estimate shipment volumes.

- Capacity Planning: Ensuring there are enough vehicles, warehouse space, and labor to meet demand.

- Network Design: Structuring supply chain hubs, routes, and partnerships for maximum efficiency.

This planning stage lays the groundwork for all subsequent processes in the logistics optimization cycle.

Logistics Route Optimization: Reducing Time and Cost

One of the most critical aspects of logistics is getting goods to their destinations on time and at the lowest possible cost. This is where logistics route optimization comes into play.Route optimization uses advanced algorithms and real-time data to:

- Identify the fastest and most fuel-efficient routes.

- Account for variables like traffic, weather, and road closures.

- Reduce empty miles by maximizing truck utilization.

For example, companies like UPS save millions annually by optimizing routes, sometimes by simply eliminating unnecessary left turns. This not only saves fuel but also improves delivery speed.

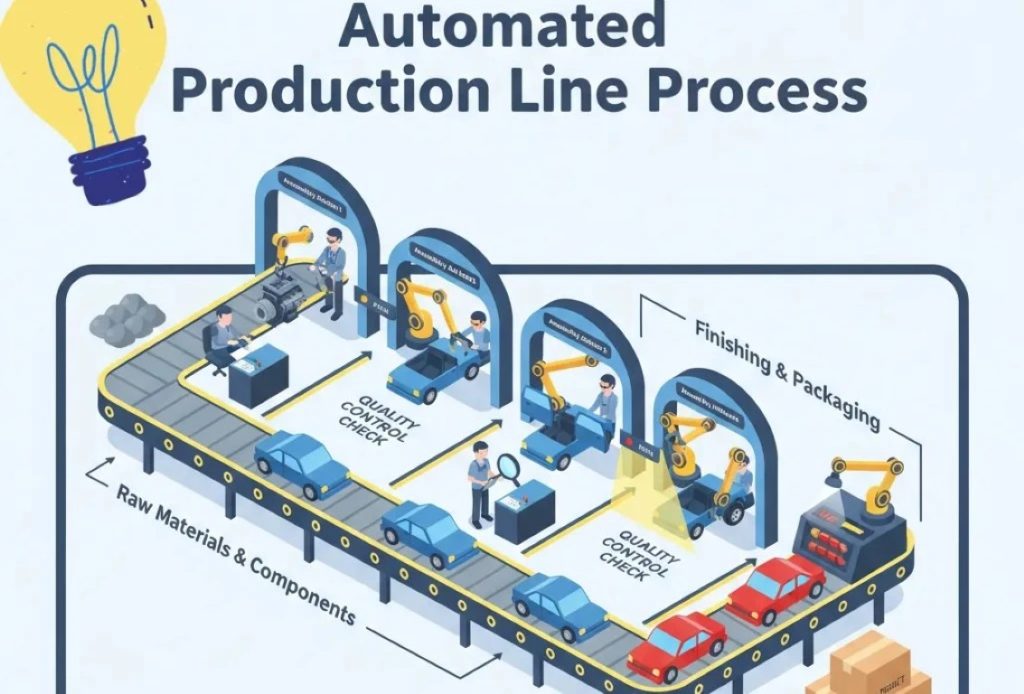

Execution: Where Planning Meets Reality

Even the best plans need flawless execution. Execution in logistics involves coordinating shipments, managing warehouses, and ensuring deliveries happen as schedule . Executive involves :

- Real-time communication with drivers and carriers.

- Warehouse automation for faster picking, packing, and loading.

- Integration of IoT and telematics for shipment visibility.

Here, it ensures smooth handoffs and continuous monitoring so that issues can be addressed instantly.

3PL Logistics Optimization: Leveraging Partnerships

For many businesses, outsourcing logistics to third-party logistics providers (3PLs) is a cost-effective strategy. But outsourcing doesn’t mean losing control. Instead, it requires strong 3PL logistics optimization practices. Benefits include:

- Access to a wider transport and distribution network.

- Shared technology platforms for better visibility.

- Scalability during peak seasons.

For example, a retailer may use a 3PL to handle cross-border shipments. By aligning systems and optimizing workflows, the retailer gains both cost savings and operational efficiency.

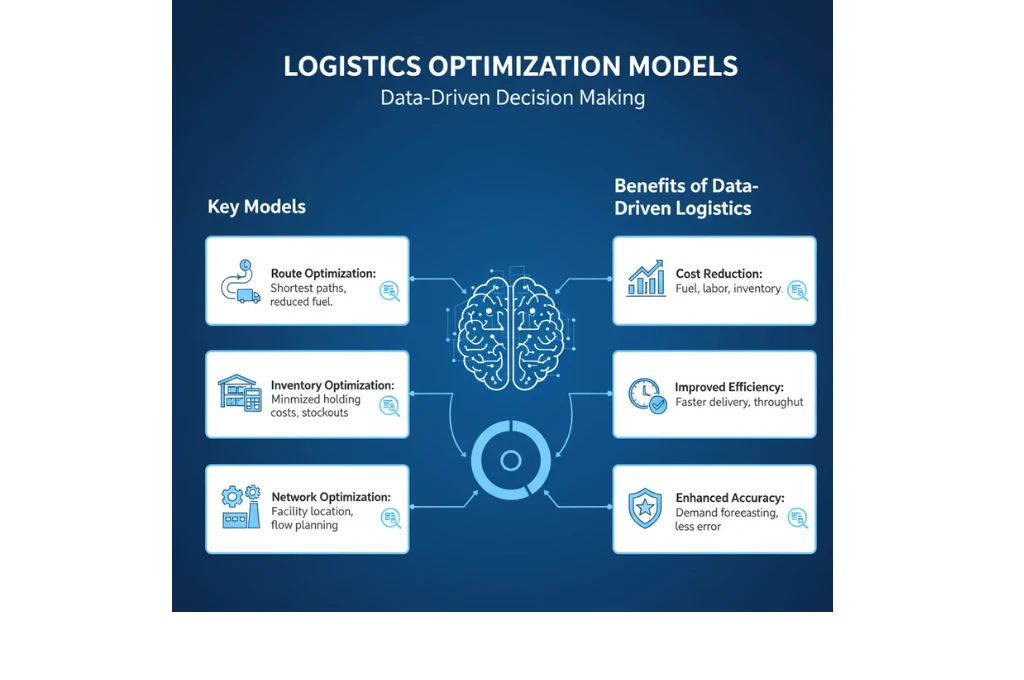

Logistics Optimization Models: Data-Driven Decision Making

Businesses can’t rely on guesswork when it comes to logistics. This is where logisitics come in. These models are mathematical or algorithmic frameworks designed to analyze and improve logistics systems.

Common models include:

- Linear Programming Models: Optimize routes, costs, and capacities.

- Simulation Models: Predict logistics performance under different scenarios.

- Heuristic Models: Provide practical solutions when exact optimization is too complex.

These models help businesses test strategies, evaluate trade-offs, and make data-backed decisions.

Logistics Optimization Process

To understand how it works in practice, let’s break down the process:

- Data Collection: Gather data on shipments, routes, fuel use, and demand.

- Analysis: Use analytics to identify inefficiencies and bottlenecks.

- Planning: Develop optimized routes, warehouse layouts, and schedules.

- Execution: Implement plans through software and communication systems.

- Monitoring: Track shipments and resources in real time.

- Feedback and Adjustment: Continuously refine strategies based on performance.

This cycle ensures logistics is not static but evolves with changing conditions.

Logistics Optimization Software: Technology at the Core

Modern supply chains are too complex to manage manually. That’s why its’s software plays a central role.

Features of such software include:

- Route planning and optimization.

- Real-time shipment tracking.

- Warehouse and inventory management.

- Predictive analytics for demand and supply.

Examples include SAP Logistics, Oracle Transportation Management, and emerging AI-powered platforms that integrate IoT data for smarter decisions.

Measuring the Impact of Logistics Optimization

How do you know if optimization efforts are working? By tracking key performance indicators (KPIs):

- On-Time Delivery Rate: Percentage of shipments delivered as scheduled.

- Cost per Mile: Efficiency of fuel and vehicle usage.

- Inventory Turnover: Speed at which stock is replenished.

- Customer Satisfaction: Direct impact of reliable logistics.

These KPIs highlight whethes its efforts are delivering measurable value.

Challenges in Logistics Optimization

Despite its many advantages, it also comes with challenges:

- High Initial Investment: Software, infrastructure, and training costs.

- Integration Issues: Legacy systems may not easily connect with new platforms.

- Data Complexity: Managing large amounts of logistics data requires advanced tools.

- External Factors: Weather, strikes, or geopolitical events can disrupt even the best plans.

Addressing these challenges requires a balance of technology, strategy, and flexibility.

Conclusion

With the rise of AI, blockchain, and IoT, the future of it looks more connected and intelligent. Predictive analytics will forecast delays before they happen, while blockchain will provide secure and transparent records of every shipment. Autonomous vehicles and drones may further revolutionize last-mile delivery.In short, it is not just a cost-saving tactic – it’s a competitive advantage that defines the future of supply chains.

FAQs

1. How does logistics optimization differ from supply chain optimization?

It focuses specifically on transportation, warehousing, and delivery, while supply chain optimization includes broader areas like sourcing and production.

2. Can small businesses benefit from logistics optimization software?

Yes, cloud-based solutions make advanced optimization tools affordable and scalable even for small enterprises.

3. What role does AI play in logistics optimization?

AI analyzes vast datasets to suggest optimal routes, predict demand, and automate decision-making in logistics.

4. How do logistics optimization models improve decision-making?

Models test different scenarios, allowing businesses to evaluate costs, risks, and trade-offs before implementing strategies.

5. What are common mistakes in logistics optimization?

Not updating data regularly, ignoring last-mile delivery, and failing to align with 3PL partners are frequent pitfalls.