The most important part of making things quickly and in large amounts is the manufacturing production line. It takes raw materials and turns them into finished products by going through a series of steps that are all connected and meant to be as quick, consistent, and high-quality as possible. Production lines help you make more while keeping costs and mistakes to a minimum. You can use them to make anything from cars to electronics.

To fully understand how production lines add value, though, we need to look at how they have changed over time, how they work in today’s world, and the problems that led to their design. We talk about these things in this article:

The fundamentals of production linesThe concept and a demonstration of a manufacturing assembly line.Why businesses need assembly manufacturing

How scheduling for the assembly line keeps everything on track

The responsibilities and actualities of an assembly line worker

Design principles, process steps, and real-life examples

By the end, you’ll not only know how a manufacturing production line works, but you’ll also be able to suggest ways to improve your own operations.

1. 1. What is a production line in manufacturing?

There are different jobs at each station on a manufacturing production line, and the stations move semi-finished goods from one to the next. In craft manufacturing, one person might make the whole thing. In production lines, work is split up into smaller, repeatable steps. This method speeds up travel, makes things run more smoothly, and keeps quality more consistent.

In the past, production lines were popular because Henry Ford put together the Model T in small parts. The product went up a conveyor belt to the next station, where the same worker or machine did the same thing over and over again. Automation, robotics, and data systems may be used in today’s production lines to coordinate these steps without any delays caused by people.

2. The Factory and Assembly Line

2.1 The Best Example of a Factory Assembly Line

People often picture factory assembly lines, especially in car plants, when they think of mass manufacturing. In this setup, a part of a product, like a car chassis, moves through a series of stations. At each station, a new part, like an engine, doors, or electronics, is added until the product is complete. This is probably the most famous way to make things these days.

An assembly line is “an arrangement of machines, equipment, and workers in which work passes from operation to operation in direct line until the product is assembled,” according to Merriam-Webster. The process usually keeps workers from moving around too much and makes sure that tasks are lined up so that the overall cycle time is the same at all stations.

2.2 Why Assembly Manufacturing Matters

Putting together parts in a planned way to make a final product is what assembly manufacturing is. It happens a lot in electronics, cars, and appliances. Because the parts can come from different vendors, the assembly line is where they all come together. Efficient assembly production cuts down on lead times, ensures that all products are of the same high quality, and makes it possible to add new features and control variations.

3. How a production line works: key steps and design

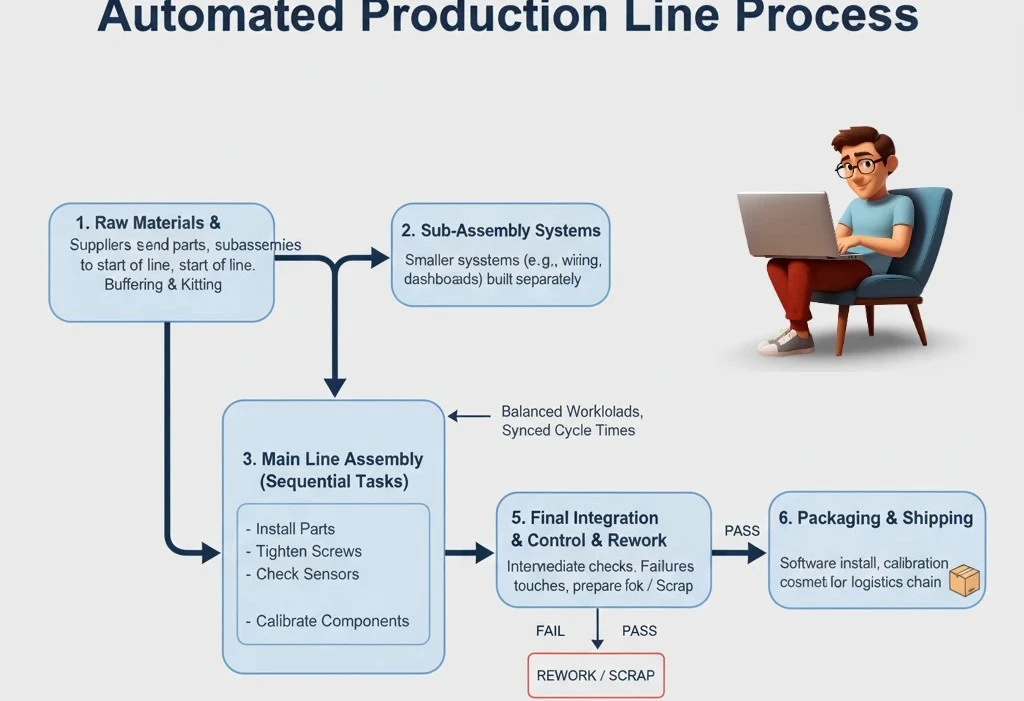

You can get a better idea of how a real-life manufacturing production line works by thinking about these common steps. Each step in a synchronised flow leads to the next.

3.1 Getting parts and setting them up

Suppliers send raw parts, subassemblies, and components to the start of the line, where they are put in order. We use buffering and kitting to make sure that each station always has the parts it needs and doesn’t have to wait.

3.2 Putting things together and putting them back together

Before integrating the main line, some systems do subassemblies. These are smaller subsystems, like wiring harnesses and dashboards, that are made separately and then sent to the main line. This makes it easier to specialise and makes things easier later on.

3.3 Main Line Assembly (Tasks in Order)

The item moves from one station to the next. At each station, a person or a machine does a specific job, like putting in parts, tightening screws, checking sensors, and so on. To save time and keep things in balance, the steps must be done in a certain order.

3.4 Checks for quality and rework

Intermediate checks help find problems before they get worse. If a unit fails a test, it might be sent to a rework station or thrown away before it affects the next steps.

3.5 Final Integration and Completion

After all the parts are put together, the product may undergo final integration work. Installing software, calibrating, adding cosmetic touches, and getting ready to pack are some of these tasks.

3.6 Putting Together and Sending

Once it’s done, the product is put in a box, labelled, and sent out for shipping or distribution. The logistics chain takes over after the production line.

Planning is what goes into these steps: making sure that the workloads at each station are balanced, the cycle periods are in sync, and the flow is optimised so that no station creates a bottleneck.

4. Scheduling in the assembly line: making sure everything goes as planned

Scheduling the assembly line so that tasks, resources, and timing all work together is one of the most important problems in a manufacturing production line.

4.1 What is the schedule for the assembly line?

Assembly line scheduling is the process of deciding which work goes to which station and when. This helps to reduce the amount of time spent waiting and keeps the line balanced. In car factories with more than one line running at the same time, scheduling can also decide when to switch from one line to another for some tasks. (Medium)

4.2 Issues and Solutions

Schedulers often use heuristics, dynamic programming, or simulation to look at their options. You can find the best path by modelling transfer times, entry and exit charges, and processing times when you have two lines that run parallel to each other. (Medium)

Adding variability (like broken units or changes in task timeframes) or switching prices makes things even harder. Modern algorithms can use AI or reinforcement learning to change schedules in real time to get the best results.

4.3 Why It Matters

Poor scheduling wastes time, causes long lines, and slows down production. A well-planned line keeps all the stations busy, speeds up the cycle time, and makes changes go smoothly. To meet demand and make the most of your time, you need to do all of these things.

5. The life and work of an assembly line worker

Even with modern production lines, people are still very important. Let’s learn more about the assembly line worker, including who they are, what they do, and how their job is changing.

5.1 What it is and what it does

A factory worker who works on an assembly line is called an assembly line worker. They have a certain job to do before the product can move on to the next station. The Cambridge Dictionary says that their jobs include putting things together, checking for quality, making small changes, and moving the item on.

5.2 Skills and Requirements

Workers need to be dependable, have good hand-eye coordination, pay attention to detail, and be able to work long hours. They stand for hours and do the same thing over and over again. Some of the tools that could be used are screwdrivers, torque guns, testing equipment, and assembly jigs. (RSS Inc.)

5.3 Change and Growth

As more and more tasks are done by machines, assembly line workers’ jobs change to include quality control, monitoring, handling exceptions, and maintenance. Workers may also have to talk to robots, watch sensors, and fix things that go wrong. To keep people safe and up to date, they need to get training.

6. Real-life examples and case studies

Examples make theory come to life. Here are some examples of production lines working in real life:

Building cars like Ford, Toyota, and Tesla

When making cars, the chassis rolls over conveyor belts while workers or robots add engines, doors, wiring, and interiors. Toyota’s “just-in-time” production uses small lots and synchronised supplies to keep things moving while cutting down on inventory. (Shipping and Receiving)

Putting electronics together

Smartphones, TVs, and other electronics go through stations where they are soldered, tested, have their firmware installed, and packaged. Micro-assembly robots, pick-to-light systems, and high-speed conveyors all make the flow of goods faster.

Things for the house and appliances

Refrigerators and washing machines may have modular assembly lines where parts like doors, controls, or tubs are made at the same time and then put together at the end. This gives the process more options.

These real systems show how different areas of study use the same basic ideas in different ways.

7. Best Practices and Design Rules for a Manufacturing Line

To make sure that a manufacturing production line runs smoothly, engineers and managers use design ideas that have worked in the past. These methods help operations run smoothly even when things change, and they cut down on downtime and waste. Let’s take a closer look at them:

Balancing the time it takes to complete a cycle

The amount of time it takes for a station to finish its job is called the cycle time. If one station takes a lot longer than the others, it slows down the whole line because it creates a bottleneck. To stop this from happening, designers make sure that the cycle times at all stations are the same so that each step takes about the same amount of time. For example, in a car factory, things like putting in an engine and attaching wheels need to be done at the right time so that they fit in with the rest of the line. Getting the cycle time just right increases throughput and keeps the flow of goods steady.

Distributing the workload and balancing the line

The work schedule needs to be fair, and so does the work itself. Line balancing makes sure that no one worker or machine is doing too much work while others do nothing. This means breaking up tough tasks into smaller, easier ones and giving them to different stations. For example, instead of having one person put together the whole dashboard, the work could be split up into wiring, positioning, and attaching at different places. Balanced lines help the system work better and keep workers from getting as tired.

Cut down on travel and movement

More mobility makes production less efficient. It takes longer and makes things less efficient when workers have to walk across the floor to get parts or look for tools. To fix this, tools are set up in a way that makes them easy to use, and supplies and parts are brought right to the place where they will be used. Automated guided vehicles (AGVs), conveyors, and robotic arms are common in today’s workplaces because they can easily bring things to the operator. Manufacturers cut down on movement, which makes the cycle time shorter and keeps workers safer and more comfortable.

Kaizen and Lean Methods

Kaizen (the idea of always getting better) and lean manufacturing are two important ideas to keep in mind when designing production lines. Lean methods find and get rid of tasks that don’t add value, like waiting, making too much, or having too much stock. Kaizen is about managers and workers making small, gradual changes to keep processes getting better. For example, a team might use a new jig to make fewer mistakes when fastening things together or move tools around to make setup faster. Lean and Kaizen work together to keep the line moving and make it better than the competition.

Layouts that are flexible and modular

Because markets change so quickly these days, manufacturing lines need to be able to quickly adapt to new items or model changes. This is possible because the layouts can be changed and are made up of different parts. Instead of rigid conveyor systems, manufacturers might use modular cells that can be moved around as needed. In electronics, for example, production lines are set up so that they can easily switch from making smartphones to tablets to other devices without having to change the whole system. Flexibility means that factories can meet customer demand without having to spend a lot of money every time a product design changes.

Checks for quality and error-proofing

It costs a lot of money to find defects late in the process. In Lean terms, these are called “poka-yoke,” and they are used on manufacturing lines to keep this from happening. These could be jigs that only let parts fit together in one way, sensors that make sure everything is put together correctly, or tests that happen at important places along the line. Early detection stops bad items from moving downstream, which means less work for you and happier customers. By putting quality checks right in the line, manufacturers lower the risk and make sure their products work.

Data and Feedback Loops

It’s very important to always keep an eye on modern production processes with data. Sensors, IoT devices, and digital dashboards tell you right away how well machines are working, how much work they’re doing, and how much time they’re not working. Management can quickly find problems and change how things work thanks to feedback loops. For instance, if a tool wears out and a station starts to slow down, data lets maintenance know before the line stops. Businesses use data to keep things running smoothly and make the system stronger.

Conclusion

A manufacturing production line is more than just a list of things to do. It’s a carefully planned system that brings together time, layout, people, machines, and planning. For an assembly line to work, all of its parts have to fit together well. This includes the idea of a factory assembly line and the scheduling details.

Robots and automation can make things easier, but people are still very important for quality control, monitoring, and fixing problems, especially on the assembly line. Also, to make things go more smoothly, modern operations are using more and more scheduling algorithms, real-time data, and adaptive systems.

If you want to build, improve, or grow a production line, you need to set clear cycle time goals, test out different scheduling methods, invest in data infrastructure, and plan for how people and machines will work together. With that foundation, your factory can stop putting out fires and start making things in a way that is stable and can grow.

FAQ’S

Q 1. What is an example of a car assembly line?

The car business is well-known for its assembly lines. The chassis is put in place, the engine is put in place, the wiring is added, the interiors are put in place, and then the car is tested and finished. This step-by-step guide for conveyor belts makes sure that production is always high and consistent. (See how Ford’s Model T line made it so people didn’t have to work as many hours.)

Q 2. What does it mean to make things in groups?

Assembly manufacturing is the process of putting together parts and pieces that were made in a factory to make a finished product. It focuses on modular processes, which are when subassemblies and component flows come together at the assembly line.

Q 3. How does the schedule work on an assembly line?

When you schedule an assembly line, you assign jobs to stations and times in a way that maximises overall throughput, minimises waiting time, and makes sure that resources are used evenly. For multi-line systems, it usually means choosing when to switch jobs from one line to another.

Q 4. What does a worker on an assembly line do?

An assembly line worker does one or more specific tasks at a station, like fastening parts together, checking them, or putting them together. They check to see that everything is working well, tell someone about any problems, and may help with small repairs or changes.

Q 5. Is assembly manufacturing good for all businesses?

Not all the time. If a business makes products that can be changed or are very different from each other, job or batch manufacturing might be better. Assembly production works well when the parts are the same and the demand is steady.

Q 6. What are the issues with assembly lines?

Some downsides are boredom and tired workers, the risk of single-point failures (if one station stops, the line slows), and the difficulty of handling product customisation or variation. It’s also harder to plan and balance as things get more different.

Q 7 How long does it take to get an assembly line ready?

For lines that are easier to understand, it might take days or weeks to analyse the schedule. For complicated lines with a lot of stations and ways to switch trains, optimisation may need to be done through repeated simulations or algorithmic scheduling.

Q 8. How has automation changed the jobs of people who work on assembly lines?

Automation takes workers away from doing the same thing over and over again and gives them jobs like overseeing, working with machines, dealing with problems, maintenance, and quality control. More and more, people who work are becoming “line integrators” instead of “manual assemblers.”

Q 9. Can assembly lines be used in small factories?

Yes. For mid-scale production, smaller companies can make mini-lines or modular stations. If small businesses use flexible conveyors and some automation, they can benefit from line principles instead of fully manual workflows.

Q 10. What sets an assembly line apart from a manufacturing line?

People often use them the same way in real life. “Production line” is a bigger word that includes all operations, while “assembly line” usually means putting things together in the right order.

Q 11. What can you do to make an existing production line work better?

Use line balancing, lower cycle variability, look for bottlenecks, add buffer phases, cross-train workers, add partial automation in key areas, and always keep an eye on KPIs.

Q 12. What is an assembly line in a factory?

In a factory assembly line, parts move through set stations, and each worker or piece of equipment has a specific job to do. The product goes from one station to the next in order until it is finished.