The pharmaceutical industry is no stranger to innovation. From breakthrough drug formulations to advanced clinical research, this sector has always evolved with science.

But in recent years, another powerful force is reshaping how pharma companies operate: the Internet of Things (IoT).

It’s an ecosystem of smart devices, sensors, cloud platforms, and data analytics working together to drive transparency, efficiency, and reliability across the supply chain, production, research, and patient care.

Let’s dive into how pharma IoT adoption is revolutionizing the sector, from manufacturing lines to your medicine cabinet.

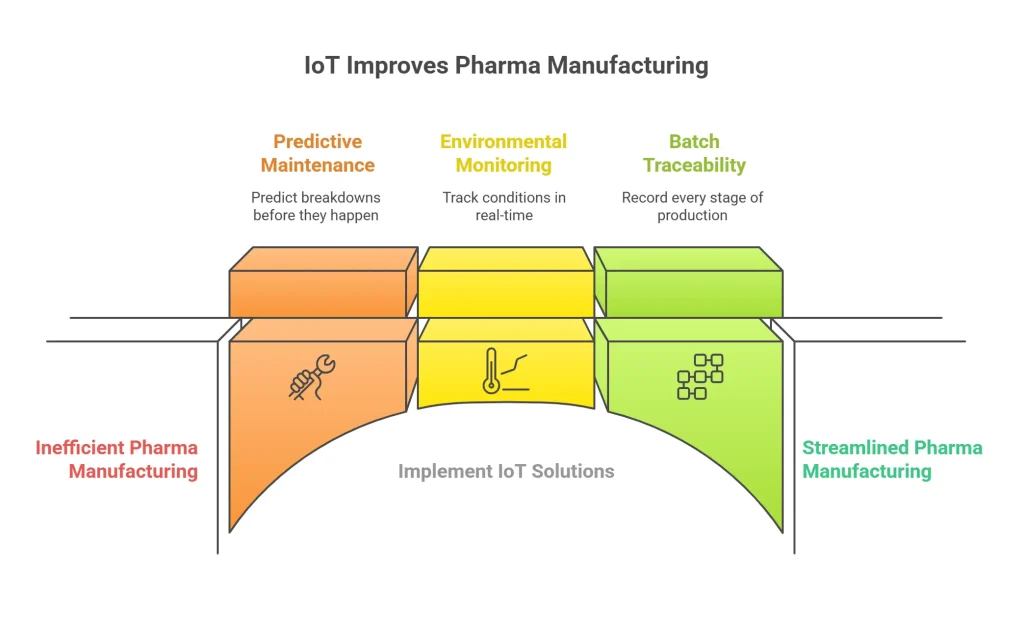

Smarter Manufacturing with IoT

Manufacturing drugs isn’t just about mixing ingredients—it’s about precision, safety, and consistency. Here’s how IoT improves pharma manufacturing:

- Predictive maintenance: Sensors monitor machine performance and predict breakdowns before they happen.

- Environmental monitoring: IoT sensors track temperature, humidity, and air quality in real-time to meet production standards.

- Batch traceability: Connected systems record every stage of production for better traceability and accountability.

Companies like Pfizer and Merck have already integrated IoT in pharma manufacturing lines to streamline processes and reduce costly downtime.

Now that we’ve looked at manufacturing, let’s explore another critical area: logistics.

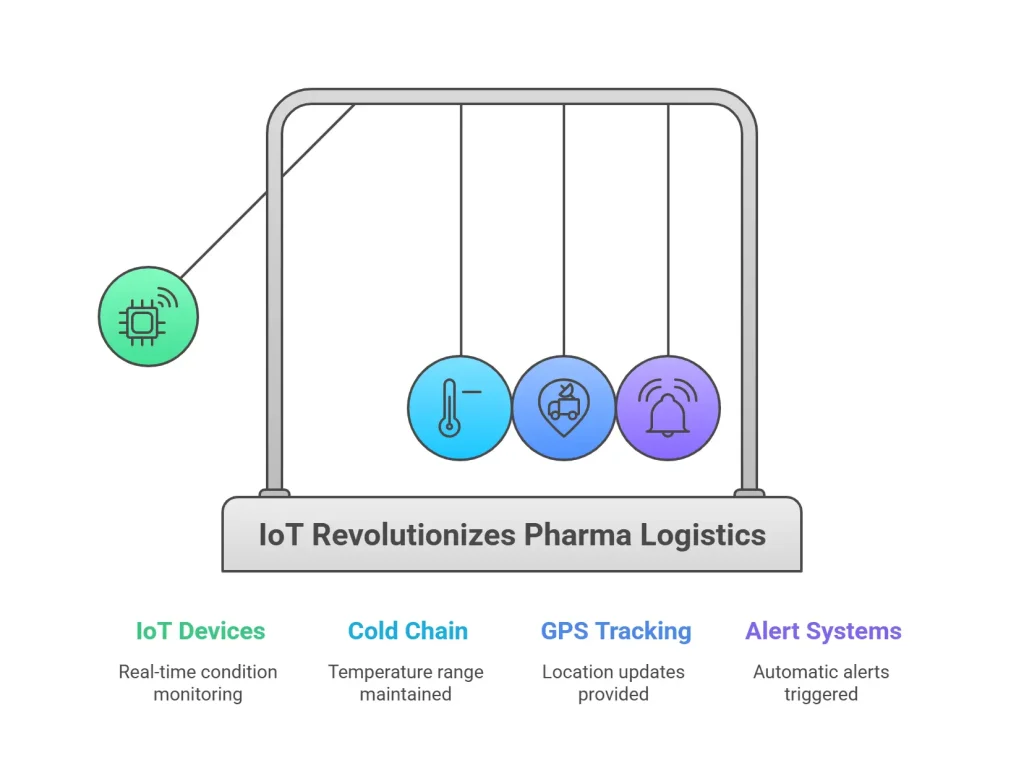

Revolutionizing Pharma Logistics

Transporting medicine, especially vaccines and biologics, requires extreme care. IoT in pharma logistics ensures that conditions remain optimal from factory to pharmacy. Here’s how:

- Cold chain monitoring: Smart temperature sensors ensure sensitive drugs stay within safe temperature ranges.

- Real-time GPS tracking: IoT trackers provide location updates to reduce delays and theft.

- Alert systems: Automatic alerts trigger if temperature deviates or a shipment is delayed.

A great example is how Moderna used IoT devices to ensure safe vaccine delivery during COVID-19, maintaining ultra-cold temperatures through end-to-end monitoring.

With logistics covered, let’s now shift focus to the supply chain as a whole.

End-to-End Visibility in the Supply Chain

IoT supply chain pharma solutions offer unparalleled transparency across sourcing, production, storage, and distribution.

| Area | IoT Solution | Benefit |

| Raw material sourcing | RFID tagging | Monitor origin and authenticity |

| Inventory | Smart shelves scanners | Avoid stockouts and overstocking |

| Delivery tracking | GPS + condition sensors | Full visibility and accountability |

This level of end-to-end visibility helps prevent counterfeit drugs and improves recall efficiency. Companies like Novartis are using RFID and IoT in pharma to track everything from raw APIs to finished packs.

Now that we understand supply chain improvements, let’s move to another critical function: compliance.

Enhancing Regulatory Compliance

In pharma, compliance isn’t optional. Failing to meet regulatory standards can cost millions and hurt lives. Here’s how pharma regulatory compliance IoT solutions help:

- Automated record keeping: IoT sensors log data automatically, reducing human error.

- Real-time audit trails: Instant access to historical data helps during FDA or EMA audits.

- Quality control monitoring: Sensors ensure consistent quality during every production batch.

Companies like Roche and Sanofi have been early adopters of IoT in pharmaceutical industry to ensure 21 CFR Part 11 compliance in electronic records and signatures.

Let’s move on now to an area where patients benefit directly: healthcare and remote monitoring.

Connecting Pharma and Patients Through Healthcare IoT

Beyond the factory floor, IoT in healthcare is bridging the gap between patients and pharma companies.

Here’s how:

- Smart pill bottles: These remind patients to take meds and track adherence.

- Wearables: Devices like heart rate monitors feed real-time data to care providers.

- Clinical trials: Remote monitoring tools reduce the need for frequent site visits.

AstraZeneca, for example, has used wearable devices in clinical trials to monitor patient vitals, improving data quality and reducing dropout rates.

Having explored patient-centric IoT, let’s now look at some of the challenges the industry faces.

Key Challenges in Pharma IoT Adoption

While pharma IoT adoption brings many advantages, it’s not without challenges:

- Data privacy and security: Patient data must be protected under HIPAA and GDPR.

- Interoperability: Devices from different vendors must communicate effectively.

- Cost and scalability: Initial investments can be high, especially for SMEs.

Despite these hurdles, companies are increasingly investing in scalable and secure IoT in pharmaceutical industry platforms.

Now that we’ve covered the challenges, let’s recap the benefits in one place.

Key Benefits of IoT in Pharma

| Area | Benefit |

| Manufacturing | Fewer breakdowns, more precision |

| Logistics | Temperature control, real-time tracking |

| Supply Chain | Visibility, anti-counterfeiting |

| Compliance | Real-time auditing, better record-keeping |

| Healthcare | Better adherence, remote monitoring |

FAQs: The Real Impact of IoT in Pharma Supply Chain and Patient Care

1. What is the role of IoT in clinical trials?

IoT devices help collect real-time patient data remotely, increasing trial accuracy and reducing the need for physical site visits.

2. How does IoT help prevent counterfeit drugs?

By using RFID tags and blockchain-based ledgers, pharma companies can track drug authenticity throughout the supply chain.

3. Can IoT reduce drug wastage?

Yes. Smart inventory systems and temperature sensors help reduce spoilage and expired stock.

4. What are some real-life examples of IoT use in pharmaceutical companies?

Major firms like Pfizer and Merck use IoT sensors for real-time cold chain monitoring, while Novartis employs predictive maintenance with AI and IoT to reduce equipment downtime. GlaxoSmithKline uses IoT to monitor environmental conditions in storage, and AstraZeneca applies connected devices for quality control during tablet production.

5. How does IoT improve drug recall efficiency in the pharmaceutical industry?

IoT enables detailed tracking of each product batch through RFID tags and connected sensors. In the event of a recall, companies can quickly pinpoint the location and status of affected batches and swiftly remove them from distribution, minimizing risk to patients and reducing operational disruption.

6. Can IoT help with regulatory audits in pharma?

Yes. IoT-enabled automated record-keeping provides instant, tamper-proof digital audit trails for temperature, humidity, and process parameters. This helps demonstrate compliance to regulators like the FDA or EMA, simplifies audits, and reduces the risk of human error during inspections.

7. What is predictive maintenance, and why does it matter for pharma?

Predictive maintenance uses IoT sensors on equipment to monitor performance in real time and forecast potential failures before they cause unplanned downtime. This proactive approach increases production reliability, saves costs, and ensures high product quality.

8. How does IoT contribute to patient safety?

IoT-enabled monitoring—across manufacturing, logistics, and patient care—ensures drug quality, authenticity, and correct storage conditions throughout the product lifecycle. Smart devices also help patients adhere to their prescriptions and alert providers if there are missed doses or abnormal health metrics.

9. What are the main barriers to IoT adoption in pharmaceutical companies?

Key challenges include high upfront investment, ensuring data privacy and security (especially under HIPAA and GDPR), achieving device interoperability, integrating with legacy systems, and maintaining regulatory compliance as rules evolve.

Conclusion

The IoT in pharmaceutical industry is no longer a futuristic concept – it’s here and evolving fast. From improving compliance and logistics to enhancing patient care and trial monitoring, IoT in pharma is rewriting how the sector operates.

With continued pharma IoT adoption, we can expect smarter, safer, and more responsive systems that benefit everyone involved.