In today’s global supply chain ecosystem, not knowing where your products are at any given time is a liability. Whether you’re shipping components across continents or managing a manufacturing floor, supply chain traceability has become non-negotiable.

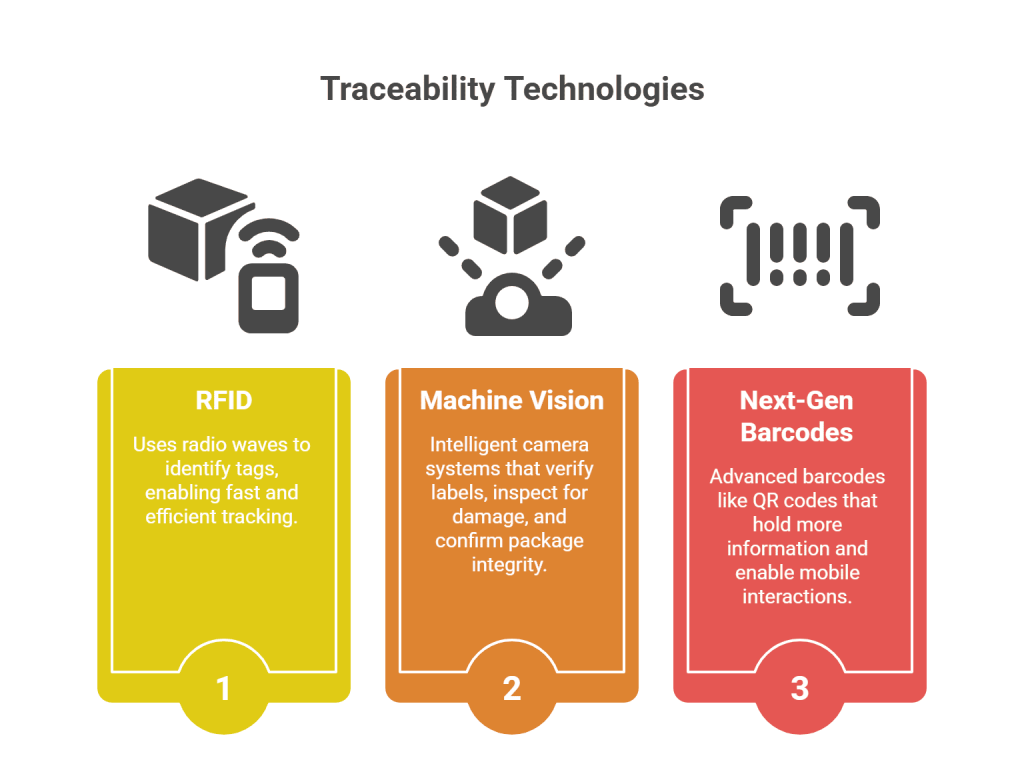

To meet increasing demand for transparency, speed, and accountability, companies are turning to powerful combinations of RFID and machine vision integration along with next-gen barcodes. This tech trio is quietly transforming operations, offering end-to-end supply chain visibility like never before.

Let’s explore how it all works together and why it matters.

Why Traceability Has Become Essential Today

Supply chain traceability isn’t just about tracking parcels anymore. It’s about:

- Ensuring product authenticity

- Managing recalls faster

- Reducing counterfeit risks

- Optimizing inventory in real-time

- Meeting compliance regulations (like FSMA, GS1, or ISO standards)

As supply chains grow more complex, traceability in manufacturing and logistics needs to be equally agile. And that’s where RFID, machine vision, and smarter barcodes come in.

1. RFID – Beyond Just Tagging

RFID (Radio Frequency Identification) is a game-changer. Unlike barcodes that need a direct line of sight, RFID readers can detect tags from a distance and even through packaging. This makes RFID supply chain tracking faster and more efficient.

What RFID brings to the table:

- Bulk scanning of hundreds of items in seconds

- Automatic data capture (no manual input needed)

- Reduced human errors

- Real-time asset tracking

Real Example: Zara uses RFID to track each item of clothing from factory to store shelf. This has shortened replenishment cycles and allowed them to respond to fashion trends faster than competitors.

Now that we understand RFID’s strengths, let’s see what machine vision adds to the mix.

2. Machine Vision: The Watchful Eye

If RFID tells you where something is, machine vision in supply chain tells you what it is and what condition it’s in. Think of it as an intelligent camera system that goes beyond traditional scanning.

Machine vision systems can:

- Verify labels, barcodes, and seals

- Inspect items for damage or defects

- Confirm package integrity

- Validate compliance marks

Real Example: Amazon uses machine vision at its fulfillment centers to scan and verify every item before shipping. This ensures fewer mistakes and happier customers.

As we see, RFID tells you where, and machine vision shows you what. Let’s bring it together.

RFID and Machine Vision Integration

Now here’s where the magic happens: RFID and machine vision integration creates a system that is fast, smart, and almost mistake-proof.

When combined, these technologies can:

- Automatically log incoming goods

- Validate product identity and condition

- Alert anomalies in real time

- Support automation in warehouses and production lines

Real Example: Boeing uses both RFID and machine vision to track and inspect thousands of aircraft parts. The result? Reduced downtime, faster maintenance cycles, and increased operational safety.

So, we’ve covered the duo. Let’s not forget the barcode – because it too has evolved.

3. Next-Gen Barcodes

Today’s barcodes are not just black-and-white lines. Next-gen barcodes like QR codes, Data Matrix, and GS1 Digital Links can hold way more information and be scanned from virtually any angle.

Benefits include:

- Carrying serial numbers, batch info, expiry dates, and URLs

- Better readability on curved or uneven surfaces

- Enabling mobile-based interactions (great for last-mile)

Real Example: Nestlé has adopted next-gen barcodes on their baby formula to let consumers trace the product’s origin via a smartphone scan—boosting consumer trust.

Now that you know the tools, let’s talk about the impact on end-to-end visibility.

Creating End-to-End Supply Chain Visibility

Achieving end-to-end supply chain visibility means connecting the dots across all touchpoints:

| Touchpoint | Tech Point | Outcome |

| Factory Floor | RFID, Machine Vision | Real-time tracking & defect detection |

| Warehouses | RFID, Smart Barcodes | Faster sorting and dispatch |

| Logistics in Transit | RFID + GPS | Route optimization, theft prevention |

| Retail Stores | RFID, Barcodes | Accurate inventory & instant audits |

Benefits of complete visibility:

- Faster decision-making

- Improved customer service

- Cost savings through inventory accuracy

- Proactive risk management

Now that we’ve seen the broader picture, what does the implementation look like?

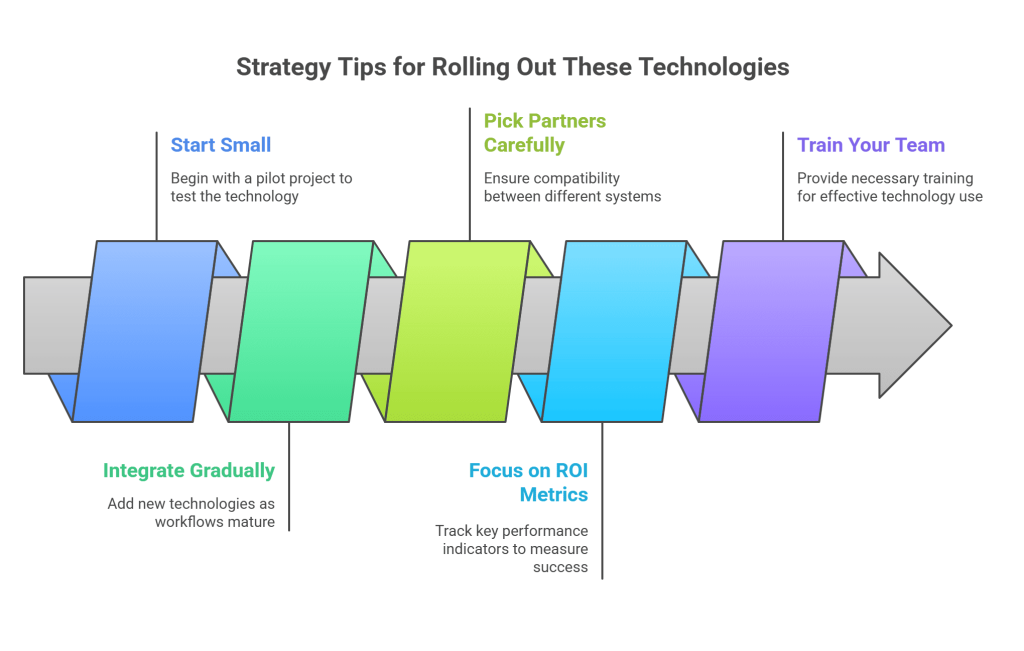

Strategy Tips for Rolling Out These Technologies

- Start Small: Begin with RFID in a pilot warehouse or with one product line.

- Integrate Gradually: Add machine vision as workflows mature.

- Pick Partners Carefully: Ensure compatibility between RFID readers, cameras, and your ERP/WMS.

- Focus on ROI Metrics: Track error reduction, faster cycle times, and improved compliance.

- Train Your Team: Technology is only as good as the people using it.

Example Tip: Unilever rolled out RFID in select plants before scaling across Asia. They tracked ROI in terms of shrinkage reduction and stock turnover improvement.

FAQs: 3 Technologies That Are Transforming Supply Chain Traceability

1. What is the biggest challenge in implementing supply chain traceability?

Integration with legacy systems and change management. Start with modular tech that can coexist with older infrastructure.

2. Can RFID completely replace barcodes?

Not always. Barcodes are still cheaper and useful in retail. RFID shines in bulk or high-value asset tracking.

3. Is machine vision expensive?

It depends on the complexity. Basic camera-based inspection systems are affordable and scalable.

4. How does this tech help during recalls?

With RFID supply chain tracking, you can trace defective batches in minutes instead of days – saving cost and reputation.

5. Does this tech work in cold storage or extreme environments?

Yes! Special RFID tags and cameras are built for such conditions and are used in industries like pharma and frozen foods.

Conclusion

Traceability in manufacturing and logistics is no longer just a compliance checkbox. It’s a competitive advantage. The synergy between RFID and machine vision integration and the intelligence of next-gen barcodes are unlocking new levels of efficiency and end-to-end supply chain visibility.

Companies like Amazon, Zara, Boeing, and Nestlé are already harnessing these tools to set industry benchmarks. The good news? These technologies are more accessible than ever.

Whether you’re just starting your digital transformation journey or looking to upgrade your current system, focusing on machine vision in supply chain and RFID supply chain tracking will future-proof your operations and strengthen trust across your ecosystem.