In the global supply chain, managing perishable goods like fresh produce, dairy, meat, and pharmaceuticals presents one consistent challenge: spoilage. Even the most optimized logistics systems can be undermined by a single overlooked variable: temperature fluctuations, humidity shifts, or light exposure. Thankfully, the rise of environmental sensors is changing the game.

These compact yet powerful devices provide real-time insights into storage and transit conditions, allowing supply chain professionals to take proactive steps in preventing spoilage. This blog explores how sensors play a pivotal role in preserving the quality and safety of perishable goods, ensuring they reach consumers in optimal condition.

Understanding the Problem: Why Spoilage Happens

Perishable goods are sensitive to environmental changes. Most spoilage is caused by microbial growth, enzymatic activity, or chemical reactions that accelerate under poor conditions.

Here are the key environmental factors that lead to spoilage:

- Temperature: Too high or too low can cause rapid degradation.

- Humidity: Excess moisture leads to mould and bacterial growth.

- Light: UV exposure can break down sensitive compounds in food and pharmaceuticals.

- Air Quality: Gaseous emissions like ethylene accelerate ripening and spoilage in produce.

Even slight deviations in these parameters can result in massive inventory loss. That’s where environmental sensors come in.

What Are Environmental Sensors?

Environmental sensors are devices that continuously monitor atmospheric conditions in a controlled space, whether it’s a refrigerated truck, cold storage unit, or retail display. These sensors collect data on variables like:

- Temperature

- Humidity

- CO₂ or ethylene concentration

- Light intensity

- Air pressure

- Shock and vibration

Data from environmental sensors can be transmitted in real-time to centralized platforms using IoT (Internet of Things) technology. When readings deviate from predefined thresholds, automated alerts are sent to relevant personnel for immediate action.

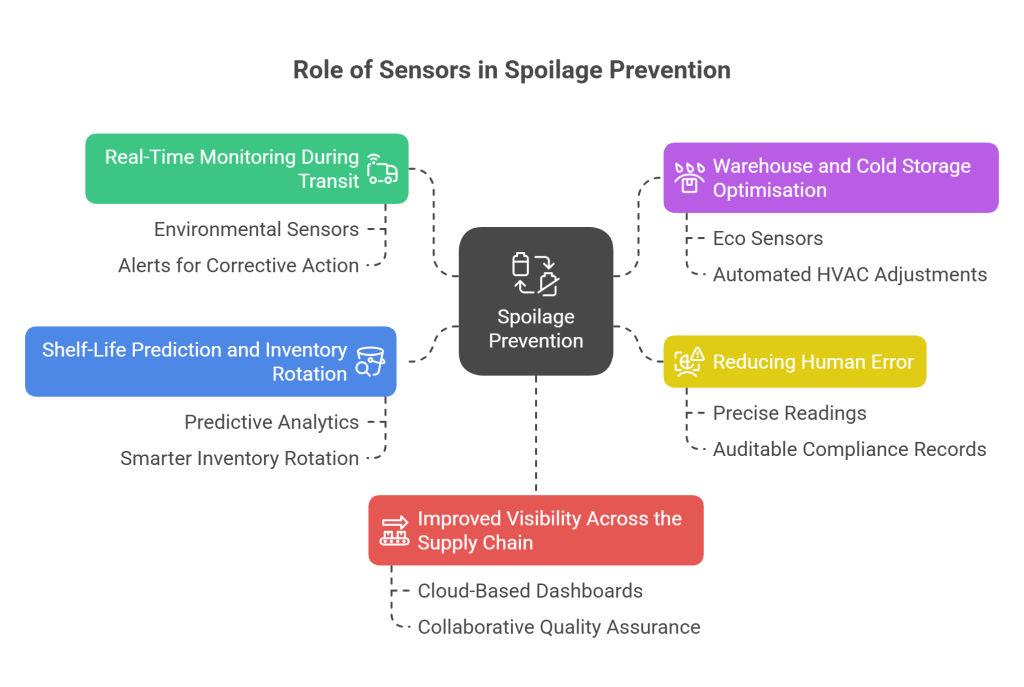

The Role of Sensors in Spoilage Prevention

Let’s explore how smart packaging sensors contribute to preventing spoilage across the perishable supply chain.

1. Real-Time Monitoring During Transit

During transportation, perishables are especially vulnerable. One failed refrigeration unit can result in thousands of dollars in losses. By installing environmental sensors in refrigerated vehicles, logistics teams can monitor internal conditions from anywhere in the world.

If the temperature spikes or humidity drops, alerts allow corrective action, rerouting the shipment, calling for a service technician, or discarding the batch before it enters the retail system.

2. Warehouse and Cold Storage Optimization

In cold storage units or distribution centres, eco sensors help operators maintain consistent conditions. These sensors can be integrated with HVAC systems for automated adjustments. For example, if humidity exceeds a certain threshold, the dehumidifier turns on automatically, preventing mold formation or packaging degradation.

3. Reducing Human Error

Manual inspections and thermometer readings are prone to error. Staff may forget to check levels or misreport data. Environmental sensors remove this inconsistency by providing precise, automated, and timestamped readings, creating an auditable record of compliance for food safety regulations.

4. Shelf-Life Prediction and Inventory Rotation

Some advanced sensors also provide predictive analytics. By analyzing the cumulative exposure of goods to environmental stressors, businesses can estimate how much shelf life remains. This data allows for smarter inventory rotation, ensuring items close to expiry are sold or used first.

5. Improved Visibility Across the Supply Chain

Using cloud-based dashboards, stakeholders across the supply chain—from farm to retailer—can access sensor data. This transparency helps pinpoint where spoilage risks are highest and supports collaborative quality assurance efforts.

Case Study: Smart Sensors in Action

A multinational grocery chain implemented environmental sensors across its cold storage trucks and warehouses. Within six months, the chain saw a 28% reduction in perishable waste. Real-time alerts helped drivers avoid routes with longer delivery times and allowed warehouse managers to detect faulty chillers before they caused product damage.

Beyond cost savings, the company also noted improved customer satisfaction, fewer product recalls, and better regulatory compliance.

Key Features to Look for in Sensors

If you’re considering implementing sensors for spoilage prevention, here’s what to look for:

- Multi-Parameter Monitoring – Choose sensors that track more than just temperature.

- Battery Life and Durability – For transportation, rugged, long-lasting sensors are critical.

- Real-Time Alerts and Cloud Integration – Ensure the system supports live data streaming and is accessible via mobile or desktop.

- Data Logging and Analytics – Look for platforms that offer visualisations and predictive reports.

- Regulatory Compliance – Ensure the sensors meet food safety standards like HACCP, FSMA, and GDP.

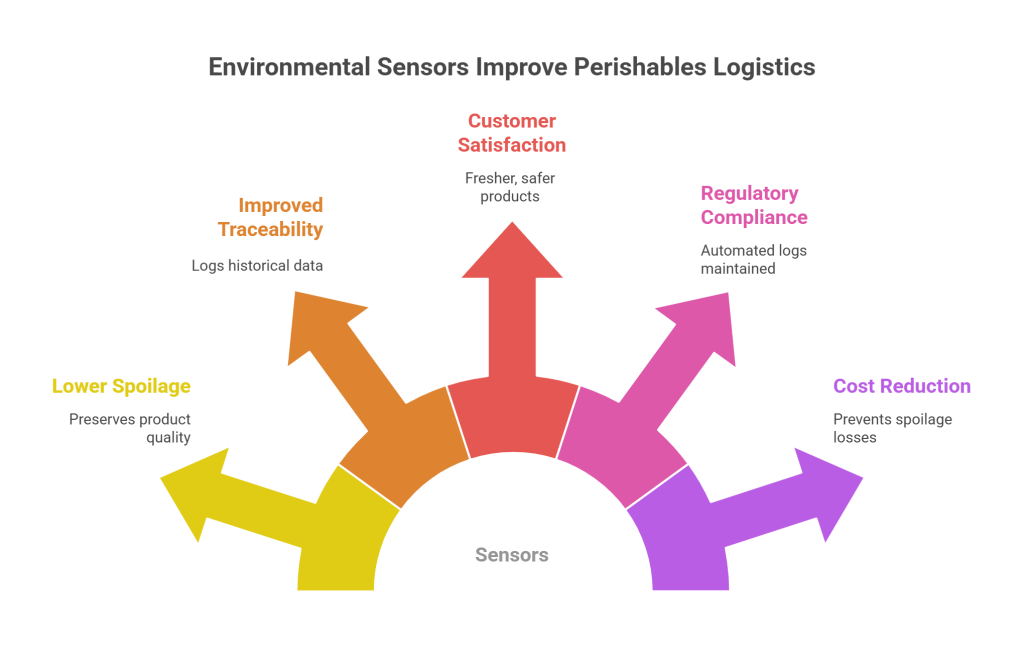

Benefits of Using Environmental Sensors in Perishables Logistics

Implementing environmental sensors can lead to transformative results across your operation:

1. Lower Spoilage Rates

Consistently maintaining optimal conditions helps preserve product quality and reduce losses.

2. Improved Traceability

Sensors log historical data, which can be used to trace where and when spoilage conditions occurred.

3. Increased Customer Satisfaction

Fresher, safer products improve brand trust and repeat purchases.

4. Regulatory Compliance

Stay audit-ready with automated logs that show your cold chain has been consistently maintained.

5. Cost Reduction

Preventing spoilage reduces the need for write-offs, returns, and emergency logistics.

Implementation Tips

Here are some strategies to implement sensors effectively:

- Start Small: Pilot the sensors in one segment—like outbound logistics—before scaling.

- Train Staff: Educate your team on reading data, responding to alerts, and performing basic maintenance.

- Integrate Systems: Sync your sensors with existing ERP, WMS, or fleet management platforms.

- Set Clear Thresholds: Define acceptable temperature/humidity ranges for each product type.

- Use Alerts Wisely: Avoid alarm fatigue by customizing alert triggers based on risk levels.

The Future of Environmental Monitoring

Environmental sensors are rapidly evolving. The next wave includes AI-powered sensors capable of not just reporting anomalies, but recommending corrective action. Others are being embedded directly into packaging, offering real-time condition tracking down to the unit level.

Blockchain integration is also gaining traction, allowing for tamper-proof records of environmental conditions across the supply chain. This could be a game-changer in enhancing transparency and food safety accountability.

As climate change increases temperature variability and energy uncertainty, the importance of environmental sensors in protecting perishable goods will only grow.

FAQs – Environmental Sensors

1. What are sensors used for?

They monitor atmospheric conditions like temperature, humidity, light, and gases to ensure safe storage and transport of sensitive goods.

2. How do sensors prevent spoilage?

By providing real-time data and alerts, they help maintain ideal storage conditions and allow immediate corrective action when deviations occur.

3. Are packaging sensors suitable for small businesses?

Yes. With advancements in IoT and affordability, even small logistics providers or retailers can deploy these sensors for quality assurance.

4. Can IoT sensors work in remote areas or long-haul transit?

Absolutely. Many models have GSM or satellite connectivity and long battery life, making them ideal for long-distance shipments.

5. How accurate are these sensors?

Modern sensors offer high precision, often within ±0.5°C for temperature and ±2% for humidity. Always check manufacturer specs.

6. Do these sensors require calibration?

Yes, periodic calibration ensures accuracy. Most suppliers provide calibration services or guidelines.

7. How do smart sensors integrate with other systems?

They can integrate via APIs into ERP, WMS, or logistics software for centralised monitoring and automation.

Conclusion

Spoilage in perishable goods is a costly and often preventable issue. Environmental sensors offer a proactive, data-driven solution to ensure that goods are kept in optimal conditions from origin to destination. By investing in these smart technologies, businesses can not only protect their inventory but also gain a competitive edge through enhanced quality, compliance, and customer satisfaction. Want a custom plan to automate and track traceability? Contact Qodenext today.