Printing in logistics is the real game-changing technique. Delivering the right product to the right place at the right time is no longer a competitive edge; it’s a fundamental requirement. This need for speed, accuracy, and visibility has led to the widespread adoption of mobile thermal printers in logistics operations.

From streamlining shipping and labelling to enhancing proof-of-delivery systems, logistics printers are redefining the way logistics companies operate. But how do they impact speed, accuracy, and return on investment (ROI)? Let’s break it down.

What Are Mobile Thermal Printers?

Printers are compact, portable devices that use thermal printing technology to generate labels, receipts, barcodes, and tickets without needing ink or toner. Instead, they use heat-sensitive media, which darkens when heated by the printer head. Because of their small size and wireless capabilities, they are often used in on-the-go environments like warehouses, delivery trucks, and field service operations.

There are two types:

- Direct Thermal Printers: Best printers for shipping labels.

- Thermal Transfer Printers: Use a ribbon for more durable prints, suitable for asset labels or cold-chain logistics.

Speed: Enhancing Workflow Efficiency

In logistics, time is money. Even a 30-second delay per shipment can snowball into hours lost across hundreds or thousands of daily transactions. This is where mobile thermal label printers shine.

1. Real-Time Printing at the Point of Activity

With thermal printers, workers no longer need to walk back and forth between their workstations and a fixed printer. Instead, they can generate labels or documents right where they’re needed—on the warehouse floor, loading dock, or delivery route. This reduces foot traffic, accelerates processes, and minimises bottlenecks.

2. High-Speed Printing with Minimal Downtime

These printers are designed for speed. Most thermal printers can print several inches per second and require minimal warm-up time. Their reliable design ensures consistent performance, which is crucial in high-volume logistics environments.

Accuracy: Reducing Human Error

Accuracy in logistics isn’t just about delivering the right package; it also ensures compliance, customer satisfaction, and cost control. Mislabeling can lead to shipping delays, returns, or even legal penalties. Mobile thermal printers help minimize such risks.

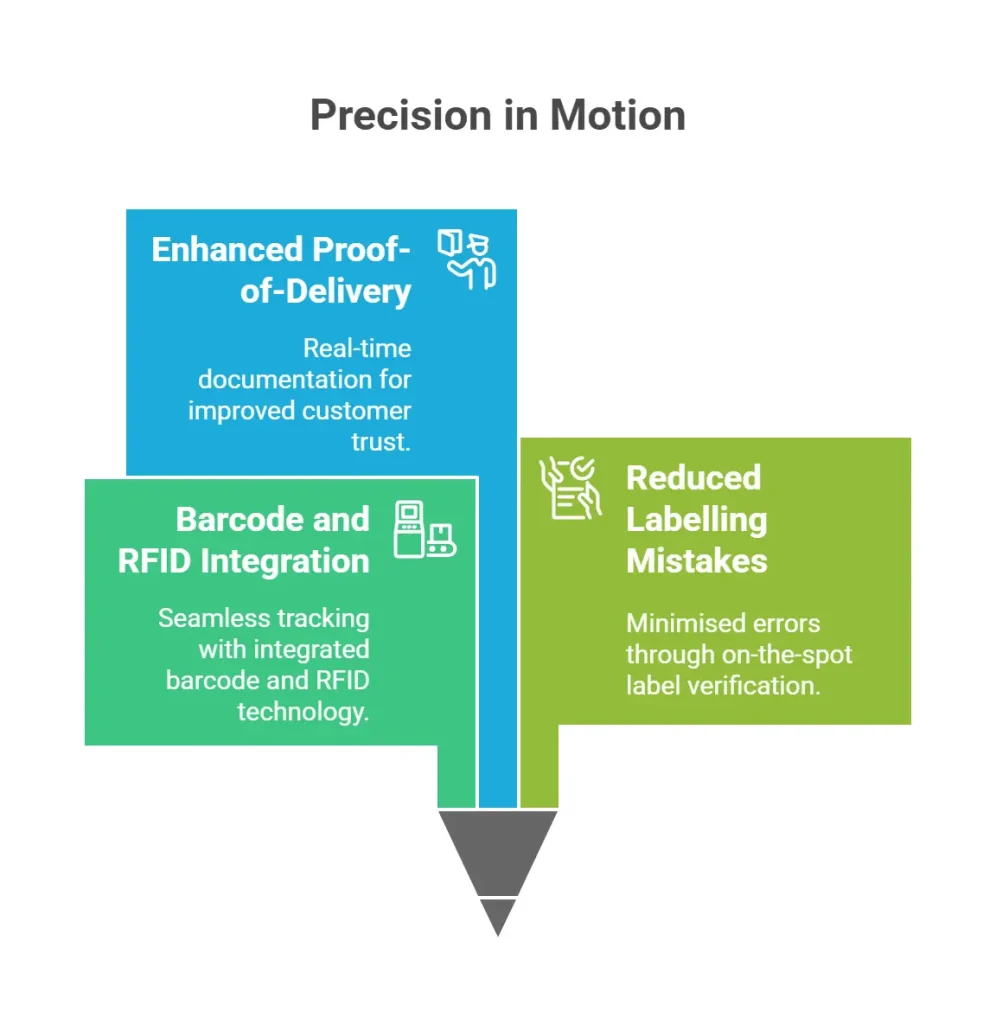

1. Integrated Barcode and RFID Support

Many modern thermal printers come equipped with the ability to print high-quality barcodes or RFID tags. This ensures easy scanning and traceability throughout the supply chain. When integrated with warehouse management systems (WMS) or transportation management systems (TMS), the labels are generated automatically with accurate data.

2. Fewer Labelling Mistakes

By bringing the printer to the point of labelling, thermal printers allow users to verify details on the spot before printing. This reduces common errors like applying the wrong label to the wrong package. They can also support different types of industrial labels, making them a versatile printing option.

3. Enhanced Proof-of-Delivery

In last-mile logistics, drivers can use mobile thermal printers to print receipts or proof-of-delivery documents in real-time. This improves customer trust and ensures all documentation is aligned and updated on the go.

ROI: More Than Just Cost-Saving

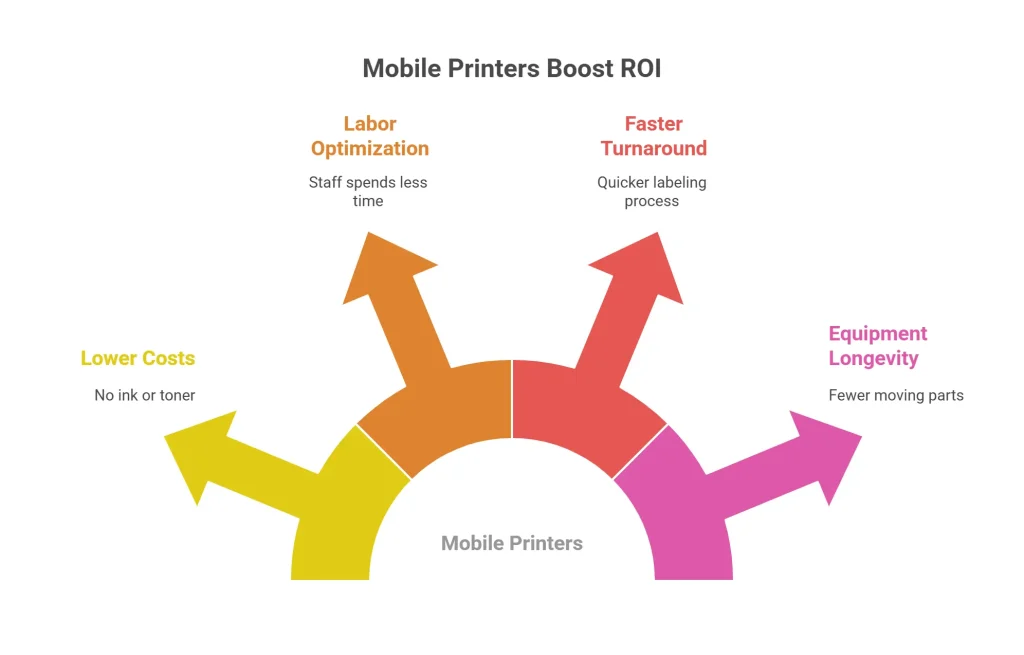

The investment in mobile printers may seem modest at first, but their long-term impact on return on investment (ROI) is significant. Let’s look at how.

1. Lower Operational Costs

Because thermal printers don’t use ink or toner, ongoing consumable costs are dramatically lower than traditional printers. Direct thermal labels, although not suited for long-term use, are perfect for short-lifecycle logistics operations, further minimizing expenses.

2. Labor Optimization

When warehouse staff spend less time walking to a centralised printer and more time processing tasks, labour efficiency increases. This enables companies to scale operations without proportional increases in labour costs.

3. Faster Turnaround Times

Quicker labelling means faster order fulfilment. Whether it’s printing shipping labels, inventory tags, or delivery slips, thermal printers help reduce order cycle times, enabling higher throughput and quicker dispatches.

4. Equipment Longevity

Thermal printers have fewer moving parts compared to inkjet or laser printers, which often results in lower maintenance and longer device lifespan. Reduced downtime means more operational uptime, directly translating to better ROI.

Use Cases in Logistics

1. Warehouse Operations

In large distribution centres, workers can use mobile printers to label inventory, packages, and shelves without leaving their stations. This improves pick-pack efficiency and reduces congestion at central printing stations.

2. Delivery and Transportation

Delivery drivers often need to provide on-the-spot receipts or print return labels. Thermal printers can handle these tasks seamlessly during delivery runs, improving the customer experience.

3. Cross-Docking and Returns Management

Speed is crucial in cross-docking. Workers can generate and apply labels instantly, ensuring packages are correctly identified and redirected. Similarly, in returns management, accurate labelling ensures products are properly tracked and re-integrated into inventory.

Challenges and Considerations

While the advantages are clear, businesses should also weigh the following before integrating thermal printers.

- Battery Life: Frequent charging may be required in high-use scenarios.

- Connectivity: Ensure compatibility with your existing systems, such as Wi-Fi, Bluetooth, or mobile apps.

- Label Compatibility: The wrong type of media can lead to fading or smudging—choose the right thermal labels for your needs.

Still, with the right planning and training, the benefits of implementing mobile printers far outweigh these challenges.

Future Outlook: Smart, Connected Mobility

The rise of Industry 4.0 and connected supply chains means thermal printers are becoming smarter. Many models now support cloud integration, remote diagnostics, and mobile device management. As logistics grows more complex, the need for flexible, reliable printing solutions will only increase.

By enabling decentralised printing, integrating with WMS and TMS systems, and supporting real-time data flow, thermal printers are key enablers of next-generation logistics operations.

FAQs – Mobile Printers

1. What are thermal printers used for in logistics?

They are primarily used for printing shipping labels, barcode tags, inventory IDs, and delivery receipts on the spot, improving accuracy and speed.

2. How do thermal printers increase productivity?

By eliminating the need for workers to travel to a central printer, reducing downtime, and enabling real-time labelling, they significantly speed up warehouse and delivery operations.

3. Do mobile-connected thermal printers require ink?

No, they use heat-sensitive paper (direct thermal) or thermal transfer ribbons, reducing recurring costs and maintenance issues.

4. Can they be used outdoors?

Yes, many rugged models are designed to withstand extreme temperatures, drops, and exposure to dust or moisture, making them ideal for field operations.

5. How do thermal printers help in last-mile delivery?

They allow drivers to print proof-of-delivery, receipts, or return labels at the delivery site, improving documentation and customer service.

6. What’s the difference between direct thermal and thermal transfer printing?

Direct thermal doesn’t use ink or ribbon and is best for short-term use. Thermal transfer uses a ribbon for more durable, long-lasting prints and is ideal for inventory or compliance labels.

7. Are they compatible with warehouse management systems?

Yes, most modern printers can be integrated with WMS and ERP platforms via Bluetooth, Wi-Fi, or APIs.

Conclusion

In a logistics environment where time is scarce and precision is priceless, mobile thermal printers are proving indispensable. They boost speed, ensure accuracy, and deliver measurable ROI through cost savings and operational efficiency.

Whether you’re running a warehouse, managing a fleet, or optimizing your supply chain, integrating Qodenext’s thermal printers is a smart move toward future-ready logistics. Contact us for personalized guidance and recommendations.