Global supply chain disruptions have become an inevitable challenge for businesses worldwide. Whether triggered by natural disasters, geopolitical tensions, or unexpected market shifts, disruptions can cause severe operational slowdowns and financial losses. Understanding how to handle global supply chain disruptions effectively can be the key to maintaining business continuity and competitive advantage. In this guide, we will explore proven strategies, technologies, and best practices to mitigate risks and enhance resilience.

Understanding the Impact of Supply Chain Disruptions

Global supply chain disruptions occur due to various economic, political, social, and natural events. Some of the primary factors include:

- Natural Disasters: Earthquakes, hurricanes, floods, and pandemics can halt production and affect transportation routes.

- Geopolitical Instability: Trade wars, political unrest, and economic sanctions disrupt global trade.

- Transportation Bottlenecks: Congestion at ports, labour strikes, and logistical failures can slow down the movement of goods.

- Demand Fluctuations: Sudden spikes or drops in demand can overwhelm or underutilise supply chains.

- Cybersecurity Threats: Digital attacks on supply chain networks can compromise data integrity and disrupt operations.

To tackle these challenges, companies must learn how to handle global supply chain disruptions proactively rather than reactively.

Strategies for Handling Global Supply Chain Disruptions

1. Build a Resilient Supply Chain

Resilience is the foundation of effective disruption management. A resilient supply chain is fast, can adapt to last-minute changes and is future-proof. Key steps include:

- Supplier Diversification: Relying on multiple suppliers from different regions reduces risk exposure.

- Nearshoring and Local Sourcing: Bringing manufacturing closer to key markets minimizes dependency on distant suppliers.

- Inventory Buffering: Maintaining safety stock for critical materials ensures smoother operations during disruptions.

2. Leverage Real-Time Visibility

One of the best ways to understand how to prevent global supply chain disruptions is to have real-time visibility over all operations. Technologies such as Iot sensors, RFID, and cloud-based monitoring can:

- Track shipments and inventory in real-time.

- Provide instant alerts on delays or route changes.

- Enhance decision-making with live data insights.

Example: During the Suez Canal blockage, companies with real-time tracking quickly rerouted shipments to minimise delays.

3. Invest in Predictive Analytics

Predictive analytics allows businesses to anticipate risks and optimise decision-making. Using demand forecasting and big data, they can anticipate future issues:

- Demand surges or drops.

- Potential bottlenecks in transportation.

- Supplier risks based on geopolitical events.

Proactive risk assessment is a critical component of learning how to handle global supply chain disruptions before they escalate.

4. Enhance Supplier Collaboration

Open communication with suppliers allows for faster problem-solving during disruptions. Strategies include:

- Supplier Relationship Management (SRM): Building strong, trust-based relationships ensures faster recovery.

- Collaborative Planning: Sharing demand forecasts and inventory plans helps suppliers prepare effectively.

- Joint Risk Assessment: Regular evaluations of vulnerabilities help both parties mitigate risks.

5. Implement Robust Risk Management Plans

A comprehensive risk management plan is essential for knowing how to handle global supply chain disruptions. This plan should include:

- Risk Mapping: Identifying vulnerabilities across suppliers, transportation, and warehousing.

- Contingency Planning: Developing alternative routes, suppliers, and emergency protocols.

- Crisis Simulation: Running regular drills to test the effectiveness of contingency plans.

The Role of Technology in Managing Disruptions

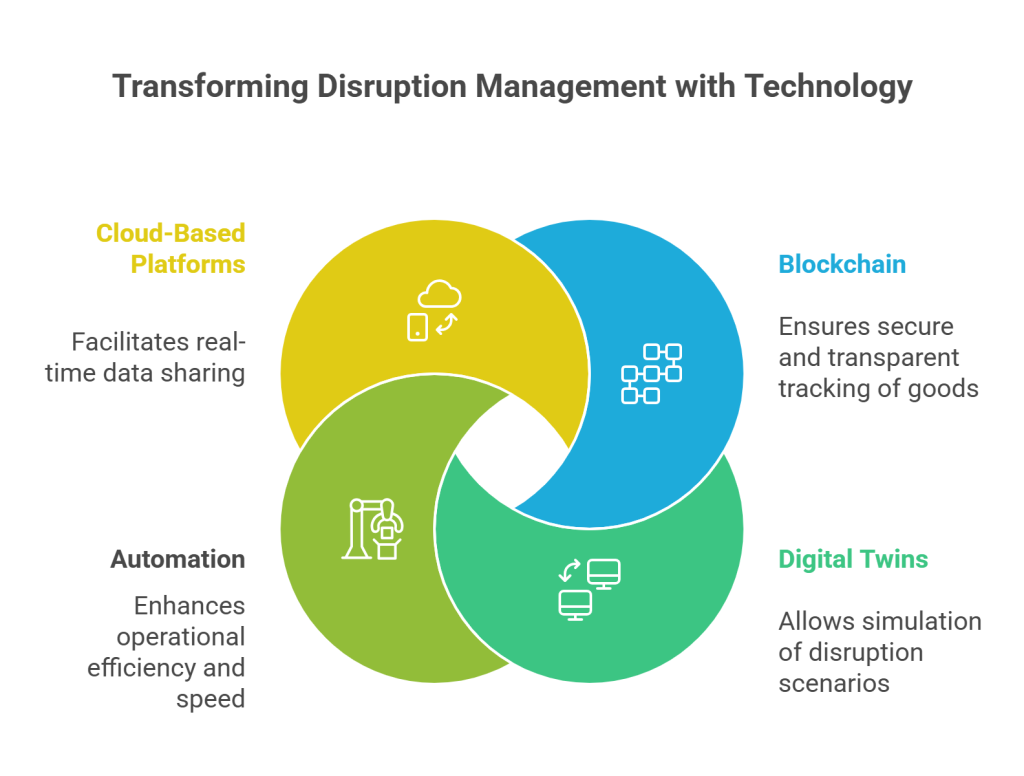

Modern technology is a game-changer when it comes to how to handle global supply chain disruptions effectively. Here are some key technologies transforming disruption management:

1) Blockchain for Transparency

Blockchain enables secure, transparent tracking of goods from origin to destination. It reduces fraud, enhances accountability, and ensures data integrity.

2) Digital Twins for Scenario Planning

Digital twins are virtual replicas of supply chain networks that allow companies to simulate various disruption scenarios. This helps in understanding the impact of certain events and preparing appropriate responses.

3) Automation for Operational Efficiency

Automation reduces human error and accelerates routine processes. Technologies like Automated Guided Vehicles (AGVS) and robotics improve warehouse efficiency and speed up order fulfilment.

4) Cloud-Based Platforms for Data Sharing

Cloud solutions enable seamless sharing of real-time data across suppliers, manufacturers, and logistics providers, ensuring everyone stays informed during disruptions.

Case Study

Case Study 1: Toyota’s Resilient Supply Chain

When the 2011 tsunami struck Japan, Toyota’s global supply chain was heavily impacted. However, due to its robust risk management and diversified supplier base, Toyota managed to recover quickly. The company had pre-established relationships with multiple suppliers, real-time monitoring systems, and a clear contingency plan, demonstrating precisely how to handle global supply chain disruptions effectively.

Case Study 2: Cisco’s Proactive Approach to Disruption

Cisco, a global leader in networking technology, is a prime example of how to handle global supply chain disruptions through proactive strategies. When the COVID-19 pandemic disrupted global supply chains, Cisco leveraged its Supply Chain Risk Management (SCRM) program to maintain operations smoothly.

Cisco’s approach included:

- Real-Time Data Monitoring: Cisco used cloud-based monitoring to track supplier performance and logistics routes globally.

- Risk Segmentation: The company segmented suppliers based on risk levels, allowing for rapid reallocation of resources.

- Collaborative Planning: Cisco maintained close communication with its suppliers, adjusting orders and rerouting shipments as needed.

This proactive stance enabled Cisco to meet customer demands with minimal delays during a period of extreme global uncertainty. Their use of data-driven insights and risk mapping allowed for quick adaptation, showcasing a strong understanding of how to handle global supply chain disruptions effectively.

FAQS – How to Handle Supply Chain Disruptions

1. What is the biggest challenge in handling global supply chain disruptions?

The biggest challenge is the lack of real-time visibility, making it difficult to identify bottlenecks and react swiftly. Iot, AI, and software sensors can solve this problem.

2. How to manage supply chain disruptions?

Technologies like blockchain, predictive analytics, and cloud platforms enhance transparency, predict risks, and optimise decision-making, enabling quicker response times.

3. Why is supplier diversification important?

Relying on a single supplier increases vulnerability. Diversifying suppliers from different regions reduces risks associated with geopolitical or environmental disruptions.

4. How do predictive analytics improve supply chain resilience?

Predictive analytics uses historical data and AI to forecast demand fluctuations and potential risks, allowing companies to make proactive adjustments.

5. What role does real-time visibility play in disruption management?

Real-time visibility provides instant updates on inventory levels, transit routes, and potential bottlenecks, enabling companies to respond quickly to changes.

Conclusion

Understanding how to handle global supply chain disruptions is more important than ever in today’s unpredictable landscape. Companies that invest in resilient supply chain strategies, real-time visibility, and advanced technologies are better equipped to navigate challenges and maintain operational stability. The key is proactive planning, strategic diversification, and leveraging technology to anticipate and respond to disruptions effectively. Want help to restructure supply chain traceability? Look no further than Qodenext to streamline logistics efficiency.