Machine vision (MV) is rapidly transforming industries by empowering machines to “see” and interpret the visual world. Moreover, this technology finds use in a wide range of applications — from automating factory assembly lines to improving medical diagnoses. If you’re curious about the potential of machine vision, this comprehensive guide will equip you with everything you need to know.

What is Machine Vision Technology?

In simple terms, a machine vision system essentially mimics the human visual system but with the power of computers. It uses cameras to capture images, powerful processors to analyse them, and software algorithms to extract meaningful information. The system then controls robots, automates decisions, and provides insights for human operators.

To understand it better, here’s a breakdown of the key components of the technology:

- Cameras: The system’s eyes! Cameras capture images of the target object or scene. The choice of camera depends on factors like resolution, lighting conditions, and frame rate.

- Lighting: Proper lighting is crucial for capturing clear images. Depending on the application, different lighting techniques like backlighting or diffused lighting might be used.

- Processing Unit: The brain of the system! The processing unit analyses the captured images using powerful processors or specialised GPUs.

- Software Algorithms: The software extracts specific features or patterns from the images using image processing and machine learning algorithms.

- Communication Interface: The system communicates with other parts of the machine or factory floor. It may send signals to robots or display results on a monitor. The interface plays a crucial role in machine vision inspection.

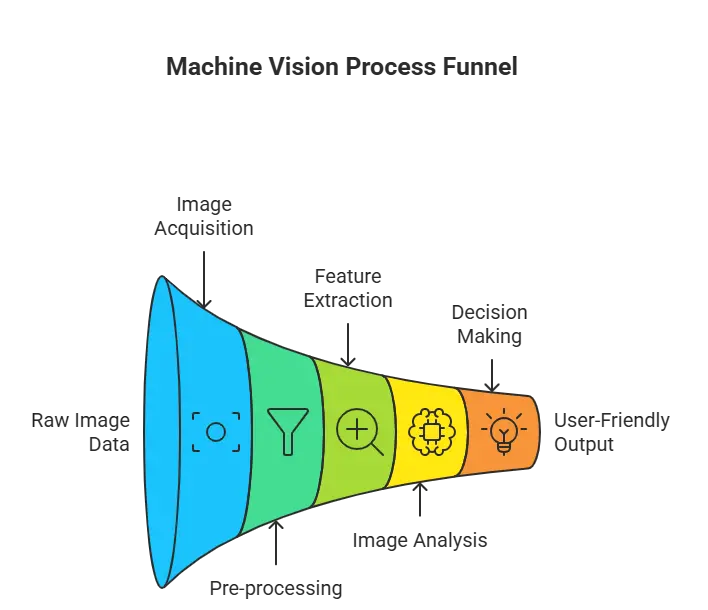

How Does Machine Vision Work?

Understanding how machine vision technology work is essential for implementation. The machine vision system workflow consists of six key stages:

- Image Acquisition: The camera captures an image of the target object or scene.

- Pre-processing: The system pre-processes the image using noise reduction or filtering to enhance the relevant features.

- Feature Extraction: The software algorithms extract specific features from the image, such as shapes, edges, or colours.

- Image Analysis: The extracted features are analysed based on pre-defined criteria or machine learning models.

- Decision Making: Next, based on the analysis, the system identifies defects, classifies objects, and guides robots in real time.

- Output: Finally, the system outputs the results, which can be used for control, data collection, or visualisation.

Applications of Machine Vision Systems

Machine vision applications are gaining prominence in a diverse range of industries. Let’s explore some examples below:

1) Manufacturing

It is used for tasks like automated inspection, defect detection, robot guidance, and quality control. In a car assembly line, for instance, the system can ensure parts are correctly positioned before welding.

2) Retail

It is used for self-checkout systems, inventory management, and product identification. In a supermarket, a machine vision system can scan barcodes at self-checkout counters.

3) Healthcare

The system assists in medical imaging analysis, surgical robotics, and pill identification. In a hospital setting, the system analyses X-rays to detect abnormalities.

4) Logistics and Warehousing

Machine vision is used for package sorting, barcode reading, and automated guided vehicles (AGVs). In a warehouse, the technology reads labels on packages to sort them efficiently.

5) Agriculture

Machine vision is used for tasks like crop health monitoring, fruit sorting, and automated harvesting. In a field, they identify ripe apples, oranges, or other fruits ready for picking.

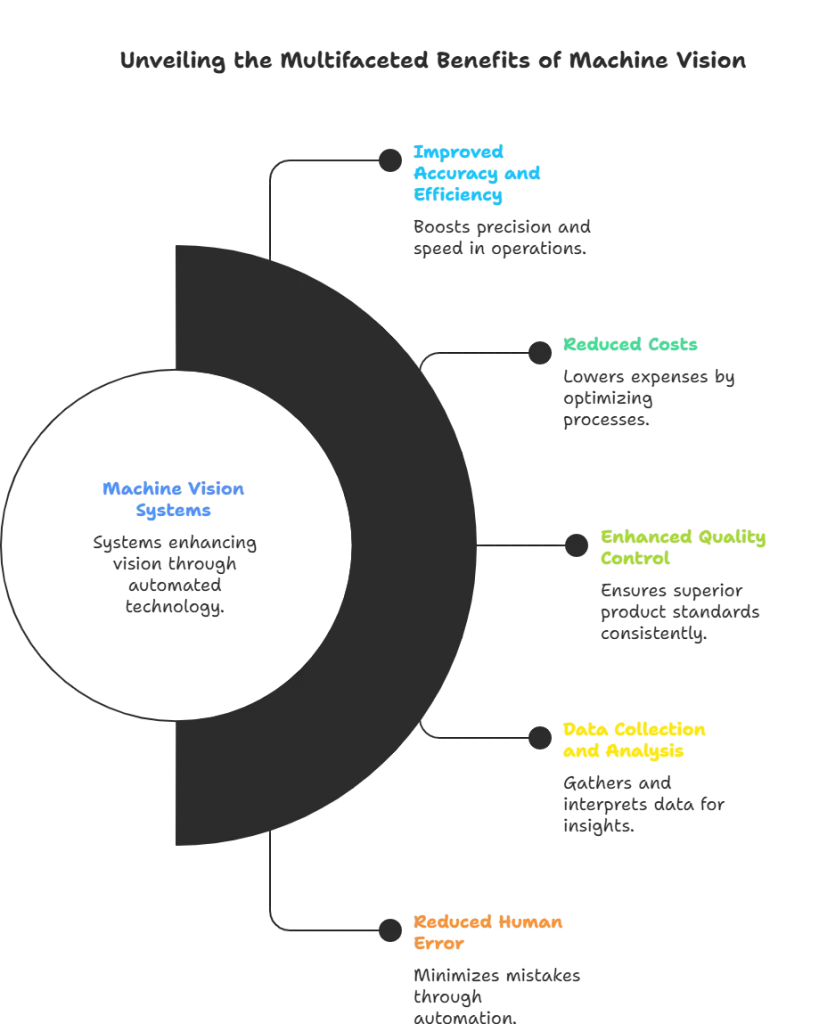

Advantages of Machine Vision Systems

Beyond applications, these visual sensors offer several advantages over traditional methods:

1) Improved Accuracy and Efficiency

Machine vision systems can perform tasks with higher accuracy and speed compared to human inspection.

2) Reduced Costs

Automation through vision technology can lead to cost savings in labour and improve production efficiency.

3) Enhanced Quality Control

Machine vision systems detect defects that humans might miss, ensuring consistent product quality.Machine vision systems can detect defects that might be missed by human inspectors, ensuring consistent product quality.

4) Data Collection and Analysis

Machine vision systems can collect vast amounts of visual data, which can be analysed to improve processes and identify trends.

5) Reduced Human Error

Automating tasks reduces the risk of errors caused by human fatigue or inattention. Furthermore, machine vision system in robotics accelerates efficiency and work output.

Conclusion

In conclusion, by fusing AI, automation, and optics, the Machine Vision System is leading the way in industrial transformation and establishing smarter, safer, and quicker production environments.

Trends like deep learning, 3D vision, and edge AI processing will reshape automated inspection and decision-making in 2025 and beyond.

Machine vision technology offers unparalleled potential to boost innovation, lower costs, and improve quality for companies looking to automate processes. For logistical automation, get in touch with Qodenext to fuel next-gen technological innovations.

FAQs: Machine Vision System: The Complete Guide in 2025

1. What are the different types of machine vision systems?

These advanced systems can be broadly categorised based on their complexity and functionality:

- Vision Sensors: These are compact, self-contained systems ideal for simple tasks like object presence/absence detection or basic measurement.

- Smart Cameras: These integrate a camera, processor, and software into a single unit, offering more processing power for complex feature extraction.

- PC-Based Systems: These high-performance systems utilise a personal computer for image processing and offer maximum flexibility for demanding applications.

2. How much does a machine vision system cost?

The cost of a system varies depending on several factors, including:

- Complexity of the system: Simpler vision sensors are more affordable than high-performance PC-based systems.

- Camera specifications: Higher resolution cameras and specialized cameras like thermal cameras will cost more.

- Software requirements: The complexity of the software algorithms needed will impact the cost.

- Customization requirements: Custom-designed systems for unique applications will be more expensive.

However, as the technology matures, costs are becoming more competitive. A good starting point is to discuss your specific needs and consider options to get a tailored quote.

3. What are the limitations of machine vision systems?

While the machine is powerful, it does have limitations:

- Lighting Dependence: Vision inspection systems can be sensitive to variations in lighting conditions, requiring careful lighting setups.

- Background Complexity: Cluttered backgrounds or complex environments can pose challenges for accurate object recognition.

- Limited Field of View: Cameras have a fixed field of view, and objects outside that view might not be detected.

- Training Data Requirements: Machine learning-based systems require a significant amount of training data to achieve high accuracy.

4. How do I get started with machine vision?

If you’re considering implementing the system, here are some steps to follow:

- Identify your needs: Clearly define the problem you want to solve or the task you want to automate.

- Research different solutions: Explore various vision technologies and system options.

- Consult with an integrator: Discuss your needs with a specialist who can recommend the right system and handle the integration process.

- Develop a proof of concept (POC): Start with a small-scale project to test the feasibility and effectiveness of your application.

- Implementation and training: Once satisfied with the POC, proceed with system implementation and operator training.

5. What are some resources for learning more about machine vision?

There are numerous resources available to deepen your understanding:

- Industry associations: Organizations like the Automated Imaging Association (AIA) offer educational resources and industry events.

- Online courses and tutorials: Several platforms offer online courses or tutorials on fundamentals and specific applications.

- Technical articles and white papers: Many software companies and technology publications provide valuable insights through articles and white papers.

6. What is the difference between computer vision and machine vision?

The former is a vast AI field involving computers to interpret information from visual images and the latter is a type of computer vision focused solely on industrial applications.

7. What is a machine vision system?

A machine vision system is basically a group of hardware and software components such as cameras, lights, lenses, processors and software that are packaged together and provide an ability for a machine or computer to capture, analyze and interpret images over real world. It then uses the interpretation to make decisions or direct activities (such as rejecting a defective part or leading a robot arm).

8. What are the benefits of a machine vision system?

Benefits include: greater accuracy and repeatability than human inspection; increased throughput; cost reduction through automation; improved data acquisition and process understanding; minimized human errors and fatigue; improved process control and product uniformity.

9. Can machine vision systems be used to inspect transparent or reflective objects?

Yes – but they need to be treated differently. Transparent and reflective surfaces are challenging to image (lights reflections, low contrast). Good results will be achieved using specialized illumination, filters, or imaging modalities to produce sufficient contrast which are then complemented with algorithms that can deal with such difficult surfaces.