Imagine yourself walking into a store with high expectations only to discover that the shelf is empty. Annoying right? Not only that but it also negatively impacts the business’s earnings and reputation. Here comes the importance of stock availability!

If you are a businessman you might have often noticed that when things aren’t available there is a loss in your sales and your customers leave unhappy. But worry not! By putting the tactics of stock availability into place you can keep your stores stocked and bring smiles to your customers’ faces.

All set to your empty shelves filled with goods? Explore our blog to learn practical strategies to improve your inventory control right now!

What is Stock Availability?

Using this measure you can determine whether any particular item is available in your stock and if it can be sold to your customers. It is the extent to which a product is available for sale without going out of stock on an average time period. This translates to several benefits, including fewer incidences of the inconveniences that customers despise – seeing stock out on the shelves.

But why does it matter so much? It is all about meeting your customer satisfaction with the product that you offer. Currently, the focus of many consumers is on convenience, and from this, they want items of their choice to be in the market whenever they want. Hence, if your business is unable to provide what they demand, they will likely turn to other options which is a situation no owner would wish to happen.

Difference Between Stock and Supply

Let’s first address the common confusion regarding the distinction between the two:

- Stock– This is the inventory of goods that your company keeps in stock i.e., what it keeps on its shelves or warehouse. It is the actual number of items that are prepared for sale.

- Supply– This refers to the full process of locating, manufacturing, and delivering those goods to the company. It is the path that the products travel to get from the manufacturer to the final customer.

Consider it this way: supply is how you obtain more of something when you need it, whereas stock is what you now have. While they are both essential to guarantee product availability, their functions within the process are distinct.

The Importance of Product Availability

It’s time to look deeper into the reasons put forward to explain why product availability is so important. Picture this: You are the owner of an online store where you sell fashionable bags. A customer navigating through your website comes across a bag they want to buy and adds it to their shopping cart, she goes to check out and then finds a message that the bag is no longer available. Criticizing, they exit your website and opt for the other sites to purchase their products. Ouch!

This means that one must ensure that the products that he or she sells are available as this has a direct relationship with the satisfaction and loyalty of the customers. If you always have what your buyers need, when they want it, they will surely keep coming back to you. But, if you have frequent stockouts, this can lead to a negative impact in terms of customer trust as well as loss of goodwill.

Moreover, product availability also has an impact on your revenue. You lose out on possible sales when products run out of stock. These missed sales can result in a considerable loss of revenue over time so, keeping your stock availability high helps you maintain a consistent flow of sales, thus increasing your profitability.

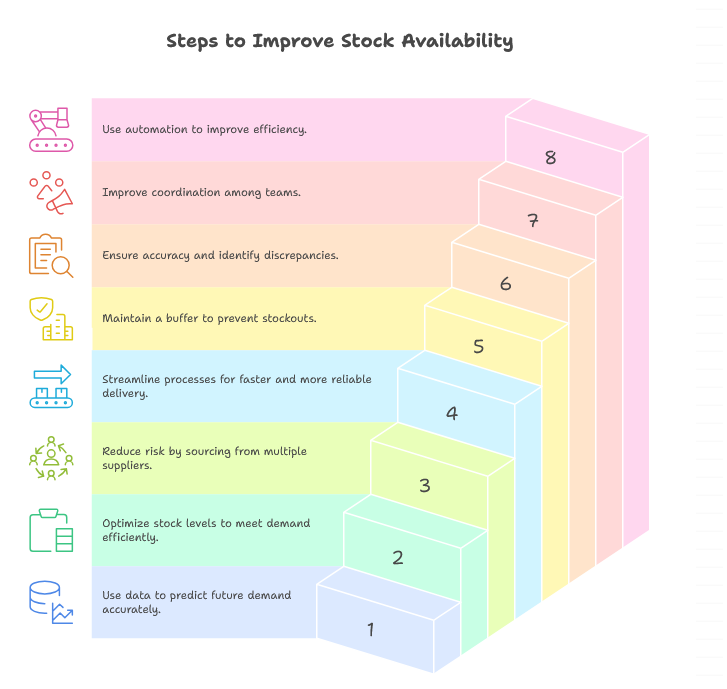

How to Improve Stock Availability?

Now, it’s time to put it into practice and consider some effective tips on how to improve the availability of your stocks. These tips would assist you whether you have a physical store an online store business or even a combination of both. Just take a look!

1. Accurate Demand Forecasting

The most crucial area of difficulty related to the problems of maintaining stocks is predicting customer demand. Miss it and end up having too many stocks or too little. The specific components that make up demand include past sales information, prevailing market trends, and fluctuations experienced over various periods of the year.

Big data is often analyzed with large tools such as ML algorithms and can also generate useful predictions that are more accurate. You can modify your inventory levels based on your expectations.

2. Efficient Inventory Management

You can use IMS to track your stock levels, establish order points, and automate replenishment to increase stock availability. This way you can be certain that you’re always aware of your stock levels and can choose when and how much to refill with the assistance of such a system.

You can also start implementing a just-in-time or JIT system, which comprises ordering products just when needed. This can reduce your storage costs and excess inventories while ensuring your products are available when customers want them.

3. Diversify Your Suppliers

Sourcing everything from a single supplier poses some risks as there could be delays and disruptions, which cause you to realize that you no longer have enough stock. You can eliminate this risk by diversifying your suppliers who can provide you with alternative sources of your products. A healthy collaboration with many suppliers can help you maintain a steady flow of your goods.

Secondly, having multiple suppliers also means bargaining over the costs and terms for more efficiencies in the supply chain.

4. Optimize Your Supply Chain

This includes increasing efficiency in operations, shortening lead time, and improving communication with your suppliers. Using information technology systems such as supply chain management software will enable you to have a clear view of everything that transpires in the entire process ranging from the production of goods to the actual delivery.

You can evaluate and analyze the activities taking place in your supply chain frequently to determine the inefficiencies and address them to ensure quicker restocking and fewer stockouts.

5. Implement Safety Stock

This is kept to guard against fluctuations in supply or demand; it refers to extra stocks apart from your usual working inventories, i.e., the ones that are not directly used in day-to-day operations. Even though suppliers may think increasing inventory is unwise, ultimately it is crucial for safeguarding against stockouts.

Take into account variables like lead time unpredictability, demand swings, and the product’s criticality while figuring out the appropriate level of safety stock. Achieving the ideal balance prevents you from using too much capital on excess inventory and guarantees that you have enough stock to handle unforeseen events.

To decide the safety quantity to be held, new factors such as unpredictable lead-time, demand volatility, and the criticality of the item come into the picture. So, having a perfect balance prevents you from using too much capital on excess inventory and guarantees that you have enough stock to handle unforeseen events.

6. Regular Stock Audits

Regular stock audits assist you in keeping precise inventory records and spotting inconsistencies early on. It’s a proactive strategy to identify errors, including lost property, theft, or incorrect data entry. Frequent audits also provide information on slow-moving inventory, which enables you to decide wisely when to offer discounts or promotions to get rid of extra stock.

Automating your stock audits with technology can help speed up the process and reduce the possibility of human error. Barcode scanners, inventory management software, and RFID technology all aid in boosting up and streamlining the auditing procedure.

7. Enhance Communication Across Teams

The sales, marketing, and inventory departments require close coordination in selling and promotional activities to avoid situations where the marketing teams create hype for specific products that are not in stock. For instance, the organization may launch a mega sale without the stakeholders from the inventory department and end up running out of stocks to sell.

Some ways include having daily or weekly meetings where new developments and progress are discussed, using data dashboards to share information on stock availability, and setting up regular check-ins to ensure everyone is aligned and focused on the organizational goal of keeping stock availability high.

8. Leverage Technology and Automation

In the age of digital transformation, automation, and technology are game-changers when it comes to stock availability. Efficiency is raised and the possibility of human error is reduced by implementing automated systems for inventory tracking, replenishment, and demand forecasting.

Consider using data analytics tools to find out more about consumer behavior, supply chain effectiveness, and market trends. By using this information, you may make better decisions and remain ahead of changes in demand.

Conclusion

It is essential to understand that the task of enhancing the availability of stocks is complex and can be solved through many strategies such as forecasting demand, efficient handling of stocks, diversifying suppliers and sources of supply, enhancing the over-supply, conducting regular audits, communication, and the use of information technologies. If you pay attention to these areas, you can easily pull your products and restock your shelves whenever they are empty, ensuring your customers are happy and your business is flourishing.

Also, keep in mind that just having a high stock availability doesn’t only mean keeping goods on your shelf; it also means giving your customers an easy and enjoyable shopping experience.

Well folks, take a deep breath and assess your current level of stock availability, then do something about it and incorporate these tactics now. Oh yes, it will go a long way in gifting you a heavy wallet and happy customers!

FAQs: Stock Availability: What it is & How to Improve It?

1. Can customer feedback improve stock availability?

Yes, listening to your customer’s comments about what they want and when they want helps tailor your inventory to meet their needs, reducing the risk of stockouts.

2. How does product bundling affect stock availability?

This can help move items slower and free up your inventory space, ensuring better stock availability and more satisfied customers.

3. What role does employee training play in stock availability?

If you train them well, they can manage your stock more effectively, spot potential issues early, and ensure accurate inventory counts, thus, boosting your stock availability.

4. What does stock availability mean in business?

Stock availability refers to whether a product is in stock and ready for sale when a customer wants to buy it. High stock availability ensures customers get what they need without delays.

5. Why is stock availability important for customer satisfaction?

When products are consistently available, customers trust your brand and are more likely to return. Frequent stockouts frustrate buyers, leading them to competitors.

6. How do stockouts affect sales and brand reputation?

Stockouts directly reduce sales opportunities and damage brand image. Customers who encounter unavailable products may switch to other businesses and may not return.

7. What is the difference between stock and supply?

Stock is the current inventory available for sale, while supply refers to the entire process of sourcing, manufacturing, and delivering goods to replenish stock.

8. How can I forecast demand accurately to avoid stockouts?

Use past sales data, seasonal trends, and predictive tools like machine learning algorithms. Accurate demand forecasting helps balance supply with customer needs.

9. What are the best tools for managing stock availability?

Inventory Management Systems (IMS), supply chain software, and tools like RFID, barcodes, or automated dashboards help track stock levels and optimize replenishment.

10. How does diversifying suppliers improve stock availability?

Relying on multiple suppliers reduces the risk of delays, shortages, or disruptions. It also gives better bargaining power and ensures a steady flow of goods.