Have you ever thought about how your favorite products move from a supplier to store shelves so quickly? Well, that’s the power of cross docking at work!

With the rising importance of time, the basics of warehousing cannot suffice in a world that is always running short of time. You might have often noticed that long times of storage and overall poor handling of the supplies increase costs and time substantially. So, what’s the solution? It helps you retrieve your goods from the receiving dock and transport them to the shipping dock without any delay.

This blog is going to decode the term cross docking starting from its explanation, types, benefits, examples, and many more. Looking for ways to improve your supply chain process and increase productivity? Dive in!

What is Cross Docking?

Let us begin with the rudiments of this strategy. It is a technique of logistics where the incoming items or goods are received and immediately transferred to the forwarding vehicles without storing them for long hours in the warehouses. Think of a relay race where one runner passes the baton to another runner without having to pause – that is exactly how cross-docking works!

If you have a typical warehouse setup, you might have to store your products for days or even weeks. But, with cross docking, you can move your items swiftly from the receiving dock to the shipping dock. It’s like a super-efficient pit stop in a car race for your goods.

Now, let’s break the process in simple terms:

- Inbound Shipments: your products will come to a cross docking terminal.

- Sorting: Items are directly sorted according to their destination, whether it is to go out of the building, to go to the next station, or to move to another location within the system.

- Outbound Shipments: Sorted products are taken to outbound trucks and sent out for delivery.

No fuss, no muss. It is also based on the idea of handling and storage, aimed at reducing the level of time and costs.

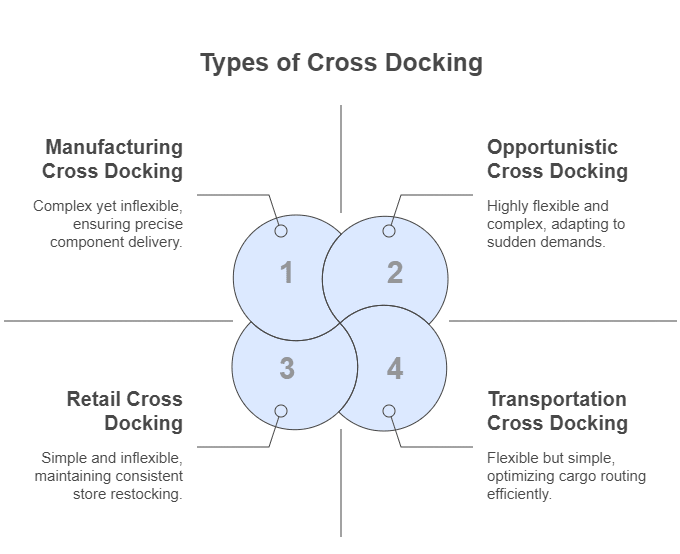

Types of Cross Docking

There are several varieties made to fulfill different requirements. Let’s examine a few typical kinds:

1. Manufacturing Cross Docking

In manufacturing cross docking, components and raw materials are taken to the depot before shipping them right away to the manufacturing locations. It’s ideal for businesses that depend on parts delivered precisely when needed to maintain production processes.

2. Distributor Cross Docking

distributor cross docking, Here raw materials and goods from different suppliers are collected and stored before they are dispatched to different markets or retail stores. It is like a back end of the supply chain where all solution portfolios are centrally managed to be delivered to customers.

3. Transportation Cross Docking

Such a type is commonly employed by transportation companies when dealing with handling cargoes that originate from different places but are metered to the same destination. It can be described as a cargo car-sharing service, wherein large numbers of vehicles are used in transporting goods.

4. Retail Cross Docking

This type is common among retailers as it aids in restocking merchandise in the stores. Purchasing from suppliers ensures that original products are received and on time are taken directly to the various stores to make available fresh merchandise on the shelves.

5. Opportunistic Cross Docking

The cross docking can also be done only when needed. Another important advantage is the ability to quickly respond to certain requirements that may become necessary at one point in a production cycle, for example, a sudden influx of orders for a particular product.

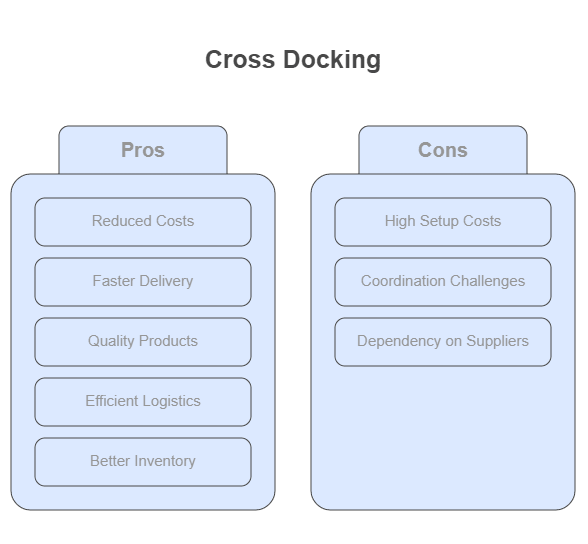

Key Benefits of Cross Docking in Supply Chain Management

Benefits of cross docking, It is important to note that it comes with several benefits that can have a significant impact on the supply chain. So, let us now look at them one by one.

1. Reduced Storage Costs

In cross docking, there is very little or usually no storage of the goods that are to be shipped. This implies that you will be enjoying cheap space costs and the other costs next to its use such as utilities and labour expenses.

2. Faster Delivery Times

Since stocks are never held for long, the overall time taken to deliver your products gets shorter. This is a big bonus for you if your firm attaches paramount importance to delivery speed.

3. Improved Product Quality

Reduced storage duration in warehouses lessens the possibility of damage to your product. This quick mobility is especially beneficial for perishable foods.

4. Increased Efficiency

Cross docking streamlines the logistics process, providing a better solution. The fewer times you shift or move your goods, the lower will be your labor costs, and the occurrence of errors.

5. Better Inventory Management

Due to short storage periods, inventory is also much easier to manage as most products are in use for a relatively short amount of time. This also results in a more effective demand forecast hence eliminating the risks of having too much stocks or not enough stock.

Cross Docking Example

Let’s take a few real-world examples to paint a clearer picture:

1. Walmart

One of the best examples of a business using cross docking well is Walmart. The moment they obtain merchandise from many other suppliers, they process and then warehouse it to the various retail outlets. It also serves to ensure that their stores are fully stocked with new merchandise to meet the market demand as well as to reduce delivery time.

2. Automobile Sector

If we consider cross decking as a tool, it is widely used in the automotive industry to ensure the availability of parts at the correct time required to assemble other parts. Suppliers deliver parts directly to production sites and they are used in making the final products on the production line. This guarantees seamless production and lessens the need for substantial warehousing.

3. Online Retailers

Cross docking is a technique that big online buying websites like Amazon use to deal with their enormous stocks and ensure speed in delivering merchandise to their customers. Most of them use it at their fulfillment centers for enhanced ordering capacity and shorter cycle time.

Conclusion

Cross docking is a strong tactic of logistics that can revolutionize the flow of commodities throughout the supply channel. Thus, it brings several advantages of decreased storage time, saving costs, and increased delivery time in the current fast-growing market.

From the information provided above, it can be seen that cross docking could be beneficial irrespective of the size of your enterprise; whether you are a small business owner planning to enhance productivity or a corporate giant with a critical necessity to optimize organizational flow. Therefore, why not give it a shot and directly check your results?

And there you have it—your complete guide to cross docking. So, keep your supply chain running smoothly!

FAQs

1. Can small businesses benefit from cross docking, or is it is it a method restricted for the big players only?

The ability to store less and deliver faster becomes the key factor that allows any business to cut through the competition by offering the best for customers.

2. Is cross docking suitable for all types of products?

No, this is efficient for items with quick turnover or products that spoil quickly like vegetables and fruits. They also include perishable goods, furniture, apparel, textiles, pharmaceuticals, and some electronics that cannot go through the cross docking process since they need prolonged storage or special handling.

3. In what ways is cross docking made possible through technology?

However, it is undeniably important, especially if cross docking is to be accomplished efficiently and effectively. Automated WMS and TMS systems help in effective sorting, tracking, and shipping of products across the warehouse. Besides, having real-time data processing and automation, accuracy and speed could be within the highest level, making your docking even better.

4. How can cross docking help a business during peak seasons or high-demand periods?

During peak seasons or high-demand periods, cross docking enables businesses to handle increased order volumes efficiently by minimizing the time products spend in storage. By streamlining the movement of goods directly from suppliers to customers or retail locations, cross docking helps companies respond quickly to surges in demand, reduces the risk of stockouts, and ensures timely deliveries without overburdening warehouse space.

5. What role does supplier collaboration play in successful cross docking?

Supplier collaboration is critical for successful cross docking, as it requires suppliers to deliver goods to the cross dock facility at precisely scheduled times. Coordinated communication ensures that inbound shipments are ready for immediate sorting and transfer to outbound transportation. Without strong supplier partnerships and adherence to delivery schedules, cross docking operations can suffer from delays, bottlenecks, and inefficiencies.

6. How does cross docking impact environmental sustainability in logistics?

Cross docking can contribute to environmental sustainability by reducing the need for large warehouse facilities, which lowers energy consumption and resource use. Additionally, by consolidating shipments and optimizing transportation routes, cross docking helps decrease the number of vehicles required for distribution, resulting in lower fuel consumption and reduced greenhouse gas emissions.

7. What types of technology are most important for efficient cross docking operations?

Efficient cross docking relies on advanced technology such as Warehouse Management Systems (WMS) and Transportation Management Systems (TMS), which provide real-time tracking and data visibility. Barcode scanners, RFID technology, and automated sorting systems are also essential, as they enable quick and accurate identification and movement of goods. These technologies help minimize errors, improve speed, and ensure seamless coordination between inbound and outbound shipments.

8. How can cross docking reduce overall logistics costs for a company?

Cross docking reduces overall logistics costs by eliminating or minimizing the need for long-term storage, which lowers warehousing expenses and inventory holding costs. It also reduces labor costs associated with receiving, storing, and picking goods. In addition, by consolidating shipments and optimizing transportation, cross docking helps lower shipping costs and improves the efficiency of the supply chain.

9. What are some common mistakes companies make when implementing cross docking, and how can they be avoided?

Common mistakes include inadequate planning, lack of coordination with suppliers and carriers, and underestimating the importance of real-time data. To avoid these pitfalls, companies should invest in robust logistics planning, establish clear communication channels with all partners, and leverage technology for real-time tracking and analytics. Proper staff training and contingency planning are also essential to handle unexpected disruptions.

10. How does cross docking support just-in-time (JIT) inventory strategies?

Cross docking supports just-in-time (JIT) inventory strategies by enabling the rapid movement of goods from suppliers to customers or production lines with minimal storage time. This ensures that products arrive exactly when needed, reducing the need for large inventory buffers and helping companies maintain lean operations. By aligning cross docking with JIT principles, businesses can achieve greater efficiency, lower costs, and improved responsiveness to market demands.