Ever wondered what happens to a product after it leaves a factory? Dive into the world of inventory movement. Let’s explore the key stages- sell in, sell out and sell through. We will show how manufacturers, distributors and retailers work together to get products on shelves and into your hands.

Mastering inventory management is crucial for success. Understanding these three stages, exploring the intricacies of each stage and how they interconnect to optimise sales and minimise losses.

From initial stock procurement to customer demand and finally, ensuring complete product depletion, we will see strategies, challenges, and best practices to navigate each stage effectively.

Whether you’re a seasoned retailer or just starting, this guide is essential for maximising profits and minimising inventory risks.

What is Sell In?

This refers to the figure of sales or units that a brand sells or references by a manufacturer or a wholesaler to its point of sale. This model of direct delivery to the point of sale began to become obsolete at the end of the 90s. A centralisation of deliveries replaced it.

The centralisation of sell-in allows significant cost savings. It is quite an improvement in the efficiency of the logistics chain. It comes at the cost of loss of visibility of sales by point of sale for manufacturers.

To recover the visibility of the sale at the point-of-sale level, manufacturers can count the examples per store that the distributors give them.

Now let’s see the other two.

What is Sell Out?

This refers to the number of sales or units of a brand or reference to sell to the final consumers at the points of sale. This is what “come out” of the store that is why the term “sell out”.

You can aggregate these sales centrally (a distribution panel is based on sell out sales). However, they mostly analyse at the point-of-sale level. For manufacturers who deliver their products on the logistics platforms of distributors, it is best to have access to sell out data at the store level. It is the only method to achieve sales visibility at the finest level.

The onus to share this information lies on the distributors. This depends on their policy as well as the commercial culture in their respective country. However, its nature is still in development.

With this let’s check out the last one.

What is Sell Through?

Think of the inventory sell-through rate as a speedometer for your products. It tells you how fast you’re selling what you buy.

The inventory sell-through rate measures inventory amount that the retailer sells regarding the amount they purchased from a manufacturer. In general, retailers utilise sell-through rates to gauge the speed at which they can sell a product and turn their initial investment into revenue.

Also, knowing how much and how quickly they can sell a product, sell-through rates also reflect the inventory turnover rate. This helps them to avoid costs related to storage or discounting.

One thing about the sell through is that there is a formula.

Sell Through Formula

You can calculate sell through rate by dividing the number of units sold by the number of units received. Then you multiply it by 100.

It is quite common to calculate it every 30 days. If a product sits on the shelf for 180 days. It is considered a “dusty inventory”. Then you need to discount it for sale to make room for seasonally relevant products. You can sell the latter for full makeup.

Here is the selling formula:

Sell Through Rate (%) = (Units Sold / Units Received) × 100

Example of Sell-Through Rate

Let’s see an example. An apparel retailer buys 200 units of a popular brand of T-shirts. Within a month there is a sales of 75 units. So, to calculate the sell through rate of the product, the retailer does this:

Sell through rate = (75/100) x100

= 0.75 x100

=75%

A sell-through rate of 75% in 30 days is quite impressive. If the retailer wants to improve the product sell-through rate in the future, they can avail of many options.

The difference between sell through vs sell in is that the former is much more important. Why?

A higher CTR means you are selling inventory faster.

This has many benefits. There is less money tied up in unsold items, storage costs are also reduced and you can free up space for new products. Thus cycle boosts profits, improves inventory management and helps you to react quicker to customer demand.

Here’s how to accelerate your sell-through rate.

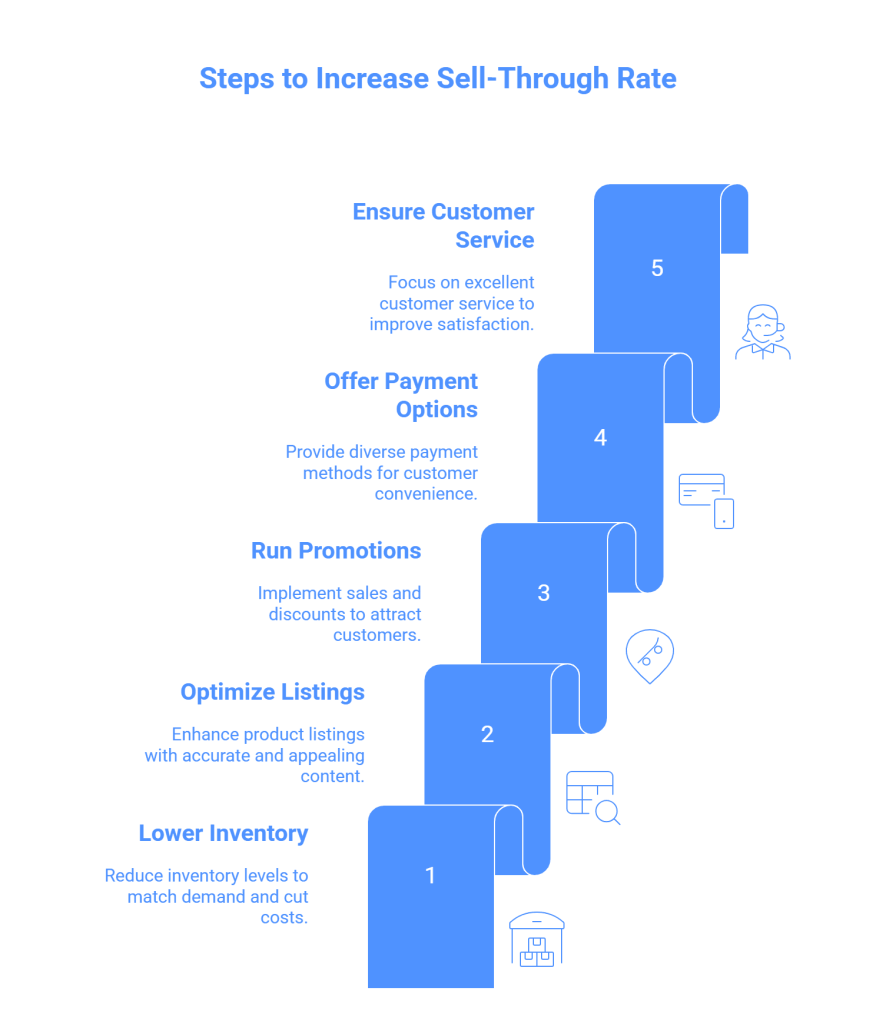

Tips for Increasing Sell-Through Rate (STR)

A high STR means your company quickly sells the inventory it receives. To keep your profits high, you need to buy back stocks to meet your customers’ demands without the need to put a discount on your products to sell off the excess inventory.

If your STR is low and items are sitting on the shelf, you’ll lose money on warehousing, shrinkage (theft) and dead stock. Thankfully, there are a few ways to increase the STR. Let’s see them.

1. Lower Your Average Inventory

If your STR is low, then your inventory forecasting may be wrong. Let’s say you sell 100 bracelets in a month and there are 200 of them in inventory. Then the STR at the end of the month is 50%.

By reducing the inventory of bracelets to 140 per month, the business can increase the STR to 71%. This lowers the carrying costs while allowing businesses to meet fluctuating customer demand.

2. Optimise the Product Listings

Increase the STR to optimise the product listings. This helps you to ensure that your tiles and descriptions are accurate and keyword-rich. Your photos too are of high quality and are visually appealing.

3. Run Promotions and Discounts

Another way to increase the STR is by running promotions and discounts. This could be anything from a percentage-off sale to free shipping or a buy-one-get-one deal.

Regardless of your choice, ensure that it is something that the customers will want to buy. In this way, you can increase sales by lowering your price or running a price promotion. This will cause a decrease in your per-unit profit, you; save on carrying costs, shrink and dead stock.

4. Offer Multiple Payment Options

It is vital to make payment methods easy for customers. This will increase the STR. offering multiple payment options like credit cards, debit cards, PayPal, PayTM or GPay can make a big difference in sales and user experience too.

5. Ensure Excellent Customer Service

Of course, you cannot ignore this. Pay attention to your customer service for increasing your sell-through rate. This means responding to customer inquiries and offering hassle-free returns. Make sure their overall experience is pleasant.

With these tips, you can increase the STR and improve your business. By effectively managing these stages, you can optimise inventory levels, reduce costs and ensure they always have the products that the customers need.

Conclusion

Mastering sell in, sell through and sell out is key to inventory success. Understanding these stages optimises sales velocity, minimises costs and ensures in-demand products. Qodenext, supply chain experts, crafts solutions to streamline your processes. Contact us to unlock your supply chain’s potential.

FAQs: The Three Stages of Inventory Movement: Sell-In, Sell-Through, Sell-Out Explained

1. What is the difference between sell in and sell out?

Sell in is when the manufacturer gets the product onto a store shelf. Sell out is when that product flies off the shelf and reaches the customers.

2. Is a high sell-out rate the same as a high sell-through rate?

Not exactly. Sell put is a retail-specific metric for how quickly they are selling a product. Sell-through considers the entire journey from manufacturer to consumer.

3. What are some buffers affecting your sell out rate?

This could happen as a result of poor product placement, low stock levels or high prices compared to competition.

4. Why is tracking sell-through rate so important for retailers?

Tracking sell-through helps retailers know how quickly products are moving off the shelves. This data helps them make smarter buying decisions, avoid overstock or dead stock, and respond quickly to demand trends, reducing unnecessary storage costs and markdowns.

5. Can sell-in data help with demand forecasting?

Yes, sell-in figures provide manufacturers and suppliers with early indicators of retailer demand, allowing for better production planning, inventory management, and reduced risk of stockouts or overstocks in the supply chain.

6. How do distributors contribute to the sell-in and sell-out process?

Distributors act as the bridge between manufacturers and retailers. They manage inventory storage, organize delivery schedules, and may share sales data (sell-out) to help both sides track product movement and forecast future needs more accurately.

7. What factors can negatively impact your sell-through rate?

Factors include poor inventory forecasting, slow-moving products, seasonal fluctuations, ineffective marketing or product displays, and limited payment options. All these can slow down sales and lead to unsold inventory.

8. How frequently should businesses calculate sell-through rates?

Most businesses calculate sell-through rates monthly or even weekly for fast-moving products. Frequent measurement allows quicker reaction to slow sales, helping optimize promotions, stocking, and pricing.

9. What’s the relationship between inventory turnover and sell-through?

Both metrics reflect how efficiently inventory is sold. A high sell-through often means high inventory turnover, indicating strong sales and low risk of excess stock. Monitoring both helps improve profitability and supply chain agility.

10. How can technology help improve sell-in, sell-out, and sell-through processes?

Modern ERP, POS, and inventory management systems automate data tracking, integrate real-time sales and inventory figures, and generate useful analytics. This software streamlines supply chain visibility, enables faster decision-making, and improves forecasting accuracy.