Imagine a warehouse operating entirely without human interference. It may sound unbelievable, almost wizard-like, but such a concept exists in the form of Dark Warehouses. It’s possible as machines and robots do not require light to see any object.

The boom in the E-commerce industry and the need for speedy operations has led to the concept of Dark Warehouses. The demand for an efficient warehouse management system has always been high.

Warehouse associates face problems in selecting and retaining the right talent in the company; this adds a lot of pressure on the stakeholders. One of the best possible ways to improve the overall productivity with efficiency is Automating processes.

Let’s understand briefly about dark warehouses and how they may take over the logistics department.

What Is A Dark Warehouse?

Dark warehouse consist of fully automatic warehouse management systems, automatic inventory, automatic material handling equipment, and automated shipment processes. These automated systems do not require light to work allowing them to run their operations in the dark.

These establishments are generally located in the outskirts of the cities and the suburbs as the land acquisition costs are lower. Most of the dark stores are also located at the retail location for the same reason that owners run thin on profits.

We have a brief understanding of Dark Warehouses. Now, Let’s dive deep into its various benefits to gain more knowledge about it.

How do Dark Warehouses Work?

Dark warehouses rely on a carefully connected ecosystem of technology. At the core are software systems like Warehouse Management Systems (WMS), Warehouse Control Systems (WCS), and Warehouse Execution Systems (WES), which coordinate the movement of robots and track inventory in real time.

Goods are often stored in Automated Storage and Retrieval Systems (ASRS), which can quickly pick items for orders. From there, robotic arms or pick-and-place systems manage individual products, while conveyor belts or Autonomous Mobile Robots (AMRs) transport items between different stations.

Advanced vision systems, machine learning, and IoT sensors ensure accuracy and monitor performance data, enabling continuous improvement. All these systems communicate seamlessly over data networks, making predictive maintenance possible and allowing warehouses to operate 24/7 with minimal downtime.

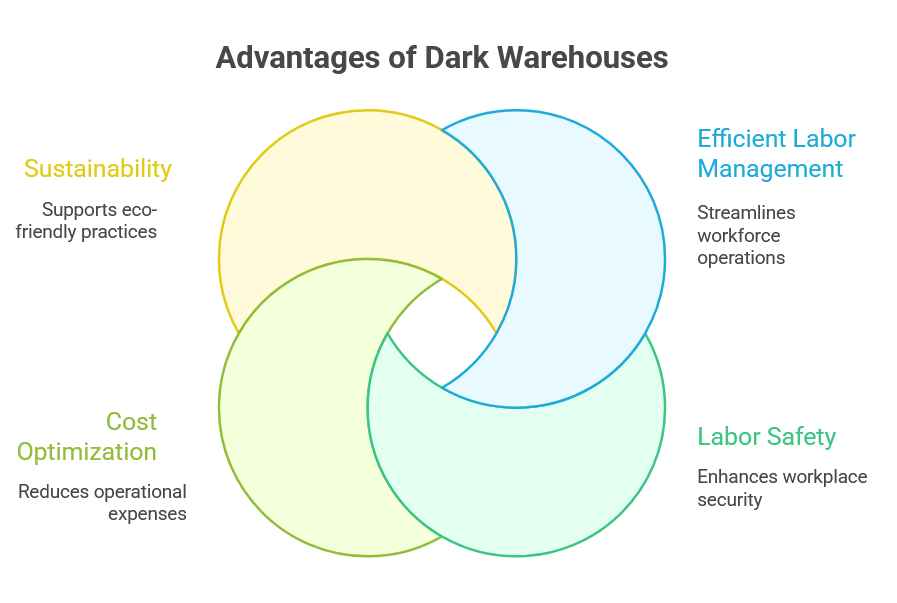

Benefits of Dark Warehouses

Automated Warehouses have shaped the business of logistics industries by seamlessly bridging the gaps between suppliers and buyers. Let us go through the benefits of these warehouses and see how they help in performance enhancement.

1. Helps In Efficient Labor Management

Automated warehouses are more labour-focused. You may wonder how. one dark warehouse example is using robots for repetitive lifting tasks, allowing humans to focus on complex decision-making. Labourers could utilize this time to upskill themselves and involve themselves in intellectual work. This results in better labor management and employment of human skills.

2. Promotes Labor Safety

Labourers in warehouses have to perform a number of high-risk tasks like carrying heavy pallets or racks, and working with toxic products (in chemical industries). In continuation of the point above, robots could take up most of these jobs and eliminate the risks for humans.

3. Optimization of Costs

While organizations have to bear the brunt of the heavy costs of warehouse modernization, the returns are quite rewarding. Organizations could optimize the expenses by reducing labor costs, handling, and storage costs. Robots could perform in a better way and the probability of errors is also low.

4. Promotes Sustainability

Sustainability has become a real deal in recent times. Every business wants to be sustainable while earning profits in the long run. Smart warehouse management systems help to control warehouse operations, optimize the use of space, and involve in practices like recycling.

Now that we have covered the benefits of warehouse automation, without further ado, let us see what the different types of warehouse automation are –

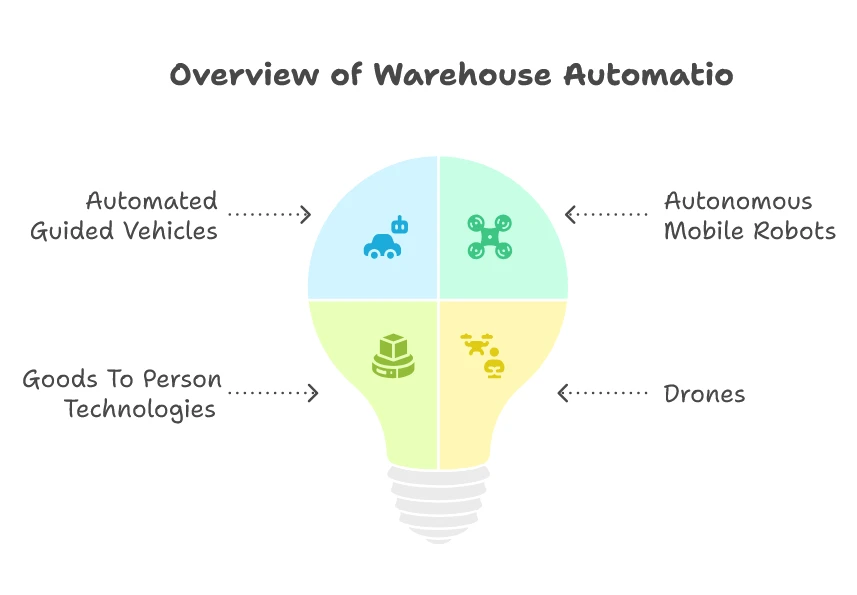

Types of Warehouse Automation

Four main types of Dark warehouse that help businesses run efficiently are-

1. Automated Guided Vehicles (AGV)

AGVs are machines made of magnetic strips, wires, lasers, cameras, markers, and other sensors to navigate a fixed path in the warehouse.

- One may use it in simple large warehouse environments with specifically designed navigation streams. You cannot use it in complex warehouses which have space constraints and use lots of humans.

2. Autonomous Mobile Robots (AMR)

AMRs are a smarter kind compared to AGVs. Unlike AGV, they do not have a fixed path, are conscious and process paths on a real-time basis.

- They can move materials autonomously without the help of markers. They can work well in warehouses that have high volumes and high labour requirements.

3. Goods To Person Technologies (GTP)

One of the most popular warehouse automation methods to drive warehouse efficiency is GTP. They help in tackling congestion by eliminating unnecessary movements in the warehouse.

- They help in the movement of goods and products with the help of carousels, conveyors, and vertical lift systems. This also reduces the chances of errors that might occur during picking and packing.

4. Drones

One of the most advanced types of warehouse automation is drones. These are vehicles which operate in the air through the employment of optical sensors, infrared cameras and barcode sensors.

- Drones could help in location of cargoes, conduct inventory counts, etc. They can reach all the corners of the warehouse and detect if anything is in the wrong location or if inventory is missing.

Having known its applications, it is necessary to understand the future of Dark warehouse. Let’s delve further into it!

Dark Warehouse- Future of Warehouse Management Systems

| Factor | Traditional Warehouse | Dark Warehouse |

| Human Involvement | High | Minimal |

| Efficiency | Moderate | Very High |

| Cost | Lower setup, higher ongoing | Higher setup, lower ongoing |

| Safety | Risky tasks for labor | Robots reduce risks |

| Sustainability | Limited | Strong focus on energy efficiency |

Every successful business has a complex warehouse management system. However, the demand for quick deliveries has led to a poor response from traditional warehousing systems.

Warehouses are the backbone of every e-commerce industry. They play a crucial role in packaging, shipping, and other business-related processes. The continuous optimization of business operations is a necessity nowadays as they have to survive fierce competition.

Traditional warehouses suffer from challenges like an increase in customer lead time, the need for manual labour, and longer time to fulfill orders.

To overcome these challenges, dark warehouse have gained popularity and it operates with minimal human interference.

Dark warehouses are well equipped with automatic systems like AI software, robotics, and that manage to enhance customer satisfaction. This reduces error and improves efficiency.

Hence, with all the benefits and types discussed above. Dark warehouse are the future of the e-commerce industry and businesses are shifting towards adopting automated systems steadily.

Conclusion

Dark Warehouses emerge as a perfect solution in a market where skilled labourers are scarce and limited in capacity. It streamlines the warehouse processes and helps in meeting the demand of customers in a digital world.

Qodenext is an excellent one-stop solution to all your warehousing needs. As technology is becoming more advanced, dark warehousing is gaining massive popularity. So, choosing the right automated systems is an essential part of business operations.

FAQ: An Introduction To Dark Warehouse

1. Is there any impact on the environment due to dark warehouses?

Absolutely no dark where houses are environment friendly due to automated systems that are energy efficient and they reduce carbon emissions.

2. Do all businesses use dark warehouses?

Dark warehouse are only suitable for businesses where the order volumes are usually high and need rapid fulfillment of orders.

3. How to address the security concerns related to Dark Warehouses?

Businesses should have proper security measures in place and work with skilled tech professionals to ensure data security.

4. Is there any drawback of Dark Warehouse?

Setting up dark warehouse requires a huge capital investment. Limited business owners can enjoy its benefits.

5. What is a Dark Warehouse?

A Dark Warehouse is a fully automated warehouse that operates with minimal or no human intervention, using robots, AI, and smart systems. This defines the dark warehouse meaning in simple terms.

6. Why are they called “Dark Warehouses”?

They are called Dark Warehouses because they do not require lighting, as machines and robots operate without needing human visibility.

7. What are the benefits of Dark Warehouses?

Dark Warehouses improve efficiency, reduce costs, enhance safety, promote sustainability, and enable 24/7 operations. Several dark warehouse examples worldwide prove these benefits in action.

8. How does warehouse automation improve Dark Warehouses?

Warehouse automation improves Dark Warehouses by using robotics, AI software, drones, and guided vehicles for faster and error-free operations.

9. What industries benefit most from Dark Warehouses?

E-commerce, retail, pharmaceuticals, and logistics industries benefit the most due to their need for speed, accuracy, and high-volume order fulfillment.

10. Are Dark Warehouses cost-effective?

While initial setup costs are high, Dark Warehouses save money long-term through reduced labor, fewer errors, and optimized operations.