In the realm of manufacturing, the synergy between predictive analytics vs prescriptive analytics stands as a cornerstone for advancing operational efficiency. Predictive analytics harnesses the power of statistical algorithms and machine learning to dissect historical data, enabling manufacturers to foresee future trends and preemptively address potential issues. This foresight proves instrumental in optimizing decision-making processes. On a parallel front, prescriptive analytics takes this predictive insight a step further by not only unraveling patterns but also prescribing actionable recommendations and strategic pathways. Within manufacturing, predictive analytics proves invaluable for anticipating equipment failures, fine-tuning maintenance schedules, and optimizing inventory management. Complementing this, prescriptive analytics acts as a proactive guide, offering specific actions to mitigate risks, amplify productivity, and streamline operations. Together, these analytical approaches empower manufacturers to navigate challenges with precision, make informed and data-driven choices, ultimately raising the bar for overall operational excellence.

Predictive vs. Prescriptive Analytics in Manufacturing

In the context of manufacturing, predictive analytics and prescriptive analytics are two distinct approaches to leveraging data for decision-making.

1.Predictive Analytics:

Definition:Predictive analytics involves using historical data, statistical algorithms, and machine learning techniques to identify the likelihood of future outcomes based on patterns and trends in the data.

Application in Manufacturing:In manufacturing, predictive analytics can be employed to forecast equipment failures, production bottlenecks, or quality issues. For instance, by analyzing data from sensors on machinery, a manufacturer can predict when a machine is likely to fail, allowing for proactive maintenance to prevent downtime.

2. Prescriptive Analytics:

Definition: Prescriptive analytics goes a step further than predictive analytics by not only predicting future outcomes but also providing recommendations on how to optimize or improve those outcomes.

Application in Manufacturing:In the manufacturing setting, prescriptive analytics can offer actionable insights into how to address predicted issues. For example, if predictive analytics indicates that a machine is likely to fail, prescriptive analytics might recommend a specific maintenance action, the optimal time to perform it, and even suggest adjustments to the production schedule to minimize disruptions.

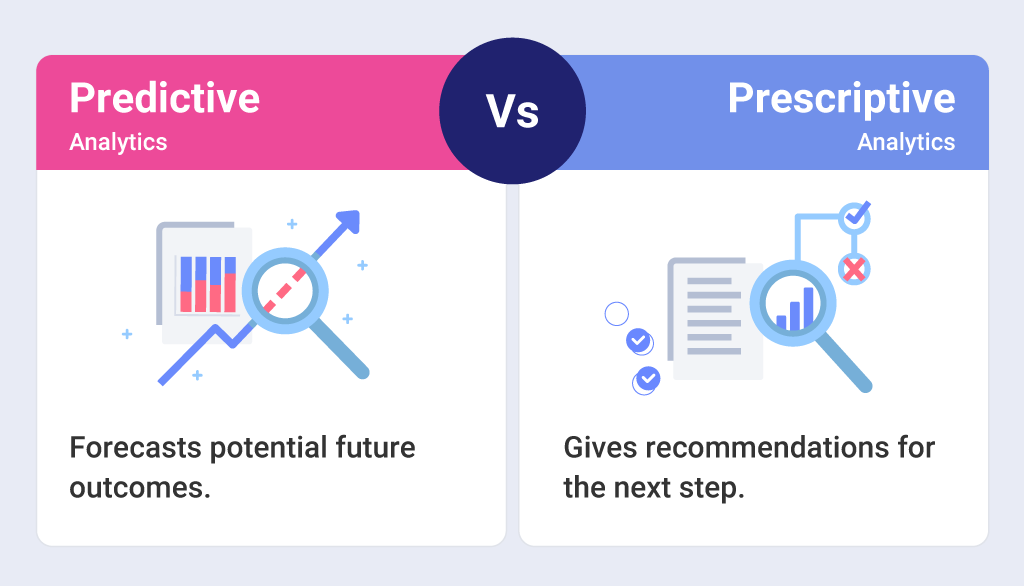

Comparison:

– Predictive Analytics focuses on forecasting future events or trends.

– Prescriptive Analytics goes beyond prediction, providing actionable recommendations for decision-making.

– In manufacturing, predictive analytics helps anticipate issues, while prescriptive analytics offers guidance on how to proactively address those issues.*

Example Scenario:

– Predictive Analytics:Identifies that a particular machine is likely to fail within the next two weeks based on historical data and performance trends.

– Prescriptive Analytics: Recommends scheduling maintenance for that machine during a planned production downtime, providing a detailed plan for the maintenance procedure, and adjusting the production schedule to minimize the impact.

While predictive analytics informs manufacturers about potential future events, prescriptive analytics takes it a step further by suggesting the best course of action to optimize outcomes based on those predictions. Both approaches play crucial roles in enhancing efficiency, reducing downtime, and improving overall decision-making in the manufacturing industry.

Prescriptive Model:

A “prescriptive model” refers to a specialized framework or approach that transcends the conventional role of describing or analyzing data. Instead, it offers explicit recommendations and guidelines for decision-making. In contrast to descriptive models, which aim to comprehend past events or current situations, prescriptive models are designed to provide actionable insights to attain specific outcomes.

Across diverse fields such as business, medicine, engineering, and data science, prescriptive models play a pivotal role by delivering solutions and informed recommendations based on predetermined criteria, goals, or constraints. These models often integrate sophisticated optimization techniques to pinpoint the most effective course of action.

For instance, in the realm of business decision-making, a prescriptive model might utilize data analysis to propose optimal resource allocation, pricing strategies, or workflow enhancements with the ultimate goal of maximizing profits. In healthcare, prescriptive models can be invaluable in tailoring individualized treatment plans by taking into account a patient’s medical history and current conditions.

A prescriptive model acts as a sophisticated tool or framework. It not only delves into data analysis but also provides tangible suggestions for actions or decisions, ultimately aiding in the realization of specific objectives.

Descriptive Predictive and Prescriptive Analytics

The Descriptive Analytics

Shedding Light on Historical Patterns

Descriptive analytics, often considered the starting point in the analytics journey, delves into the depths of historical data. By unraveling past events, it answers the fundamental question, “What has happened?” Organizations leverage this phase to identify patterns and trends, crucial for evaluating their performance over time. Through a meticulous examination of key performance indicators (KPIs), businesses gain a panoramic view of their historical landscape.

The Predictive Analytics:

Forecasting Tomorrow Based on Yesterday

Predictive analytics takes the baton from descriptive analytics, propelling us into the realm of the future. Employing statistical algorithms and machine learning, this stage seeks to answer, “What is likely to happen?” It involves constructing models that, like seasoned fortune-tellers, forecast future trends and behaviors. Businesses harness the power of predictive analytics to make informed decisions, mitigating risks and preparing for the ever-evolving landscape of possibilities.

The Prescriptive Analytics

Guiding Decisions with Precision

Prescriptive analytics, the pinnacle of the analytical pyramid, goes beyond understanding the past and predicting the future. It answers the crucial question, “What should be done about it?” This advanced stage employs cutting-edge algorithms and simulation techniques to recommend optimal courses of action. By providing actionable insights, prescriptive analytics empowers organizations to make strategic decisions, enhancing efficiency, and achieving superior outcomes.

The synergy of descriptive, predictive, vs prescriptive analytics creates a roadmap for organizations navigating the intricate world of data. Descriptive analytics lays the foundation, predictive analytics illuminates the path, and prescriptive analytics guides decisions with precision. As we embrace the future of data-driven decision-making, understanding and integrating these analytics approaches will be key to unlocking new possibilities and achieving sustained success.

Frequently Asked Questions (FAQs)

How does predictive analytics benefit manufacturing operations?

Predictive analytics in manufacturing foresees potential issues, enabling proactive maintenance and minimizing downtime.

What sets prescriptive analytics apart from predictive analytics?

Prescriptive analytics not only predicts outcomes but also recommends optimal actions, guiding decision-makers towards efficiency.

Can predictive analytics be used for supply chain optimization?

Yes, by forecasting demand and potential disruptions, predictive analytics aids in optimizing the supply chain in manufacturing.

How do descriptive analytics contribute to manufacturing analytics?

Descriptive analytics provides insights into historical data, forming the foundation for predictive and prescriptive analytics.

Are there integrated solutions that encompass all three analytics types?

Yes, comprehensive analytics solutions often integrate descriptive, predictive, and prescriptive analytics for a holistic approach in manufacturing.

Conclusion

In the competitive landscape of manufacturing, the synergy of predictive and prescriptive analytics can significantly elevate Qodenext’s operational prowess. Predictive analytics equips the company with the foresight to anticipate and prevent disruptions, while prescriptive analytics empowers decision-makers with actionable strategies to navigate challenges seamlessly. By incorporating these analytics-driven approaches into their manufacturing processes, Qodenext can position itself as an industry leader, achieving a harmonious balance between proactive problem-solving and strategic decision-making. In essence, the marriage of predictive and prescriptive analytics under the Qodenext brand umbrella is poised to revolutionize manufacturing practices, fostering a culture of efficiency, innovation, and sustained success.