Did you know that the Indian automotive industry exports vehicles to over 180 countries across the globe? From bustling cities to remote villages, Indian-made cars are a familiar sight. This remarkable feat is not just the result of innovative design and engineering but also a testament to an efficient supply chain management system.

In today’s ever-evolved business topography, an efficient supply chain is the beating heart of successful enterprises, and its harmonious coordination ensures products reach the right place at the right time. To achieve this delicate balance between efficiency and responsiveness, companies need to embrace strategic approaches that streamline their operations. In this article, we delve into the steps required to create an effective, responsive, and efficient supply chain.

Understanding Supply Chain Efficiency

Supply chain efficiency refers to the streamlined flow of products, information, and resources from the initial supplier to the end consumer. It involves minimising waste, reducing costs, and optimising processes to ensure that every element of the supply chain contributes positively to the overall performance of the system.

A Closer Look into Supply Chain Responsiveness

Supply chain responsiveness, on the other hand, revolves around the agility and adaptability of a supply chain to respond to sudden changes in demand, market trends, or external disruptions. A responsive supply chain ensures that a company can quickly pivot its strategies to accommodate unforeseen circumstances without sacrificing operational efficiency.

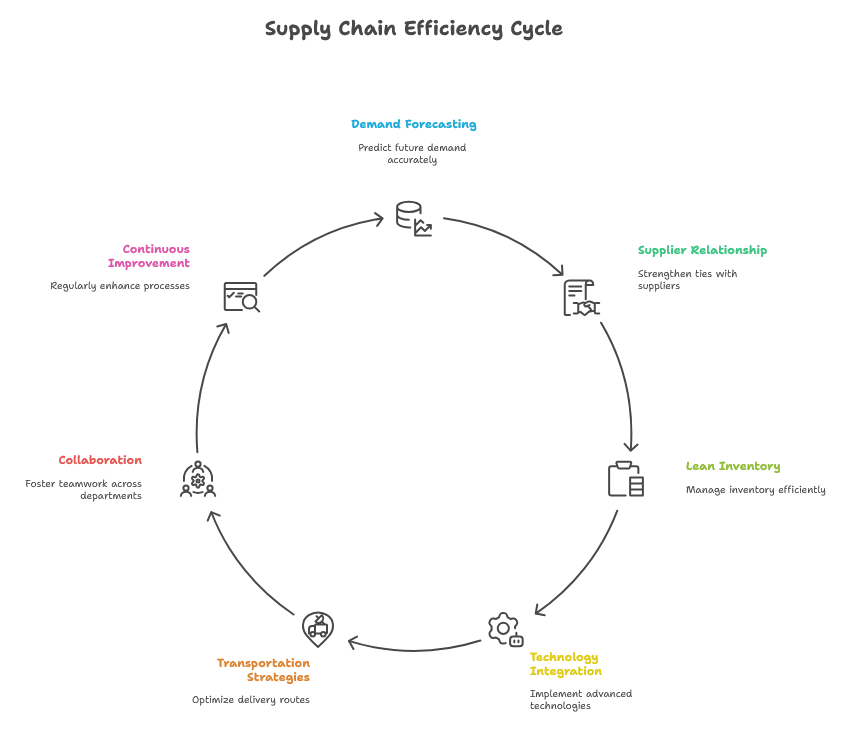

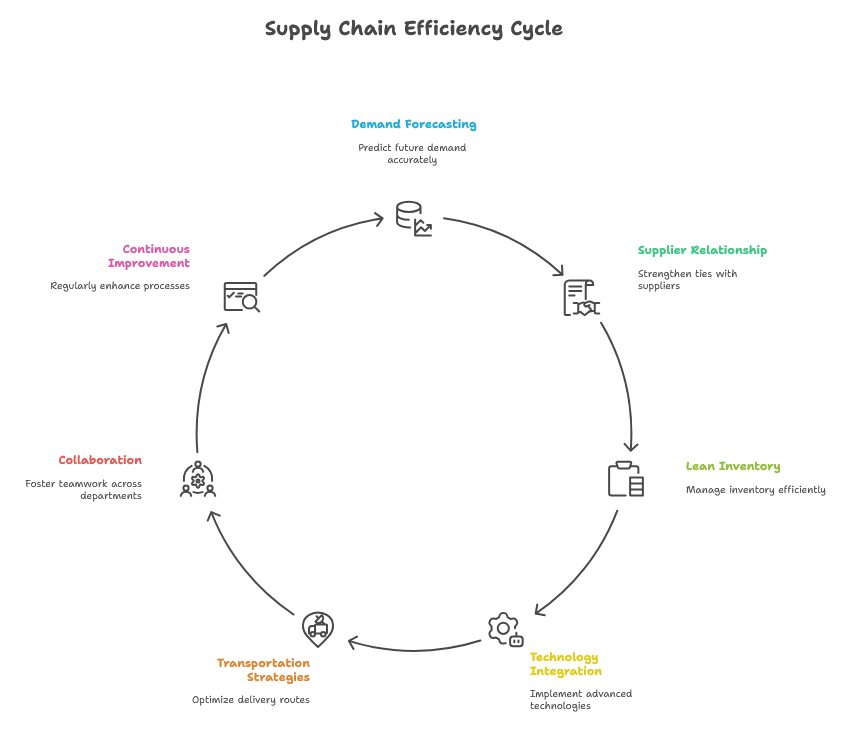

Enhancing Supply Chain Efficiency: A 7-Step Roadmap

- Demand Forecasting Excellence

Accurate demand forecasting forms the bedrock of an efficient supply chain. For instance, Tata Motors uses predictive analytics to anticipate seasonal demand for vehicles, which has helped the company reduce stockouts by 18% and improve production planning efficiency.

- Supplier Relationship Enhancement

Collaborative partnerships with suppliers are crucial. To effectively manage a supply chain, companies should establish open lines of communication, share real-time data, and work together to optimise inventory levels and lead times. This collaborative effort ensures that the supply chain remains agile and responsive to changes. For insights on overcoming common hurdles, see The Most Common Supply Chain Challenges and How Rugged Tablets Can Help.

- Lean Inventory Management

Efficient supply chains avoid stockpiling excessive inventory. By embracing lean inventory management principles, companies can reduce carrying costs, minimise waste, and improve cash flow. Just-in-time (JIT) inventory systems can be employed to ensure that inventory levels match demand closely.

- Advanced Technology Integration

To effectively manage a supply chain, companies must leverage technology solutions such as warehouse management systems (WMS), enterprise resource planning (ERP) software, and transportation management systems (TMS). These tools provide real-time visibility, automation of routine tasks, and data-driven insights that enhance decision-making. Understanding fundamentals of logistics management systems can further enhance your approach.

- Optimised Transportation Strategies

Transportation is a critical link in the supply chain. Implementing efficient routing, mode selection, and carrier management strategies can significantly reduce transportation costs and lead times. Moreover, embracing sustainable transportation practices contributes to both cost savings and environmental stewardship.

- Cross-Functional Collaboration

Siloed departments can hinder supply chain efficiency. Companies should promote cross-functional collaboration between departments like procurement, production, logistics, and sales. This holistic approach ensures that all aspects of the supply chain are aligned towards common goals.

- Continuous Improvement Culture

Supply chain management is a dynamic field. To remain efficient, companies must foster a culture of continuous improvement. Regularly reviewing processes, benchmarking against industry best practices, and implementing innovative solutions can drive ongoing efficiency gains.

4 Key Practices for Supply Chain Management

- Data-Driven Decision Making: Harness the power of data analytics to make informed decisions that optimise supply chain processes. Data-driven insights help in identifying trends, bottlenecks, and opportunities for improvement. Learn more about how to increase supply chain transparency.

- Risk Management Strategies: Develop robust risk management strategies to anticipate and mitigate potential disruptions. This proactive approach enhances supply chain resilience and ensures smooth operations even during unexpected events.

- Sustainable Practices: Integrating sustainable practices not only aligns with corporate social responsibility but also enhances supply chain efficiency. Sustainable sourcing, packaging, and transportation contribute to cost savings and improved brand reputation. Explore the supply chain challenges of the food processing industry for sector-specific sustainability insights.

- Talent Development: Supply chain efficiency relies on skilled professionals. Companies should invest in training and developing their workforce to understand the intricacies of supply chain management and drive innovation.

- Cost Reduction: Apply proven techniques to cut costs without compromising quality. Check out supply chain cost reduction techniques you should start practicing now.

Major Challenges: Overcoming Hurdles in Supply Chain

Efficient and responsive supply chains are undoubtedly the backbone of successful businesses. However, achieving this harmony between streamlined operations and adaptability is not without its challenges. In this section, we will explore some common obstacles that companies often face on their journey towards an effective supply chain and how they can overcome them. For example, the pharmaceutical sector is evolving with trends like serialization and cold chain management see key pharma supply chain trends to keep an eye on.

- Demand Volatility

Fluctuating customer demands can disrupt even the most well-optimised supply chains. To address this, companies can implement advanced demand forecasting models that consider historical data, market trends, and external factors. This enables proactive planning and allocation of resources.

- Supplier Reliability

Overdependence on a single supplier can create vulnerabilities. Diversifying the supplier base and fostering strong relationships with multiple suppliers can mitigate risks and ensure a steady flow of materials even during supply disruptions.

- Technological Integration Challenges

While technology is a boon for supply chain efficiency, integrating different software systems can be complex. Adopting scalable and adaptable technology solutions that can communicate seamlessly can help overcome integration hurdles.

- Last-Mile Delivery Complexity

The final leg of delivery often presents challenges due to varied customer locations and preferences. Employing innovative solutions like crowdshipping or partnering with local delivery services can optimise last-mile delivery.

- Environmental Concerns

Balancing efficiency with sustainability is a pressing concern. Embracing eco-friendly practices, such as optimising transportation routes and minimising packaging waste, can create a more environmentally responsible supply chain.

- Talent Shortage

Skilled supply chain professionals are in high demand. Companies can invest in training and development programs to upskill their existing workforce and attract new talent.

- Data Security and Privacy

As supply chains become more data-driven, ensuring the security and privacy of sensitive information is critical. Robust cybersecurity measures and compliance with data protection regulations are essential.

By addressing these challenges head-on, companies can strengthen their supply chain’s efficiency and responsiveness. Each hurdle presents an opportunity for innovation, collaboration, and growth, ultimately leading to a more resilient and agile supply chain.

Efficiency in Motion: Qodenext’s Supply Chain Success

Experience how we at Qodenext, an e-commerce pioneer, transforms supply chain efficiency through these vivid examples:

- Streamlined Inventory Management: Qodenext employs real-time data analysis and demand forecasting to maintain optimal inventory levels. This approach has helped reduce excess stock by 15–20% and cut storage costs by approximately 12% annually, according to industry benchmarks from Supply Chain Dive.

- Agile Order Processing: Through automation, Qodenext accelerates order processing, from the moment a customer clicks ‘buy’ to product dispatch. This swift response enhances customer satisfaction and loyalty.

- Dynamic Route Optimization: Qodenext’s supply chain incorporates intelligent route optimization software, reducing delivery lead times. This results in faster deliveries and decreased transportation expenses.

- Collaborative Supplier Relationships: Qodenext nurtures collaborative partnerships with suppliers, sharing insights and forecasts. This cooperation ensures a consistent flow of high-quality products, reducing production delays.

- Data-Driven Decision Making: Qodenext harnesses data analytics for informed decision-making. They monitor consumer trends, adapting their supply chain promptly to align with changing demands.

- Synchronised Warehousing: Qodenext’s warehouses are strategically located, minimising shipping distances and improving overall efficiency, leading to cost savings and reduced carbon footprint.

Final Words

As the Indian e-commerce market continues to flourish, the race for efficient supply chain and responsiveness becomes more intense than ever. Effective supply chain management is no longer an option; it’s a strategic imperative. By implementing the steps and best practices outlined in this article, businesses can streamline their operations, minimise costs, and keep customers delighted.

In this journey toward supply chain excellence, Qodenext’s innovative solutions stand as beacons of success, showcasing how the convergence of technology and smart strategies can unlock unparalleled efficiency and responsiveness. So, embrace the future of supply chain management, and take your business to new heights with the power of efficiency and responsiveness.

Frequently Asked Question’s

1. What is supply chain efficiency?

Supply chain efficiency refers to optimizing the flow of products, information, and resources from suppliers to end consumers. It aims to minimize waste, reduce costs, and streamline processes so every part of the chain contributes positively to overall performance.

2. How is supply chain responsiveness different from efficiency?

Responsiveness is about a supply chain’s agility and adaptability its ability to quickly respond to changes in demand, market trends, or disruptions while efficiency focuses on minimizing waste and optimizing resources.

3. Why is demand forecasting important?

Accurate demand forecasting helps align production and distribution with actual market needs, reducing excess inventory and preventing stockouts.

4. How does technology improve supply chain efficiency?

Technology provides real-time visibility, automates routine tasks, and offers data-driven insights for better decision-making. Tools like warehouse management systems (WMS) and transportation management systems (TMS) are key enablers.

5. What are the benefits of a lean inventory management system?

Lean inventory management reduces carrying costs, minimizes waste, improves cash flow, and ensures inventory levels closely match demand.

6. How does cross-functional collaboration help?

It breaks down departmental silos, ensuring procurement, production, logistics, and sales are aligned towards common supply chain goals.

7. How can companies make their supply chains more sustainable?

Companies can make their supply chains more sustainable by using eco-friendly packaging, optimizing transportation routes to reduce emissions, sourcing materials from responsible suppliers, and adopting circular economy practices like recycling and reusing materials.

8. What technologies are transforming supply chain management today?

Technologies such as Artificial Intelligence (AI), Internet of Things (IoT), blockchain, and robotics are reshaping supply chains. They enable real-time tracking, predictive analytics, automated warehousing, and secure data sharing — all of which enhance efficiency and transparency.

9. How does supply chain visibility improve performance?

Supply chain visibility allows businesses to track goods, materials, and information at every stage. This transparency helps detect delays, manage risks, reduce costs, and make faster, more accurate decisions — ultimately leading to better customer satisfaction.

10. What is the role of AI in supply chain forecasting?

AI enhances forecasting by analyzing large volumes of data, identifying patterns, and predicting future demand with high accuracy. This helps companies align production and inventory with market needs, reducing overstocking and minimizing stockouts.