Did you know that barcodes play a vital role in the manufacturing industry, enhancing efficiency, accuracy, and overall productivity? With the advancement of technology, integrating a barcode system into manufacturing processes has become increasingly popular. In fact, according to recent statistics from the Confederation of Indian Industry (CII), over 70% of manufacturing units in India have successfully implemented barcode systems to streamline their operations. In this article, we will provide you with a step-by-step guide on how to implement a barcode system in your manufacturing unit, highlighting the benefits, and introducing the Qodenext barcode implementation process as a superior and innovative solution.

What are Barcodes?

Before delving into the implementation process, let’s first understand what barcodes are and how they function. Barcodes are machine-readable codes consisting of a series of parallel lines, numbers, and characters that represent specific information about a product, such as its unique identification number, price, or batch number. These codes are typically printed on labels or directly on products and can be scanned by barcode scanners or mobile devices equipped with barcode scanning capabilities.

Barcodes serve as a universal language that allows for quick and accurate data capture. By scanning a barcode, relevant information about a product can be instantly retrieved from a centralised database, eliminating the need for manual data entry and reducing the chances of human error. This technology has revolutionised various industries, including manufacturing, by enabling businesses to automate processes, improve inventory management, enhance traceability, and streamline operations.

How Barcodes are Used in Manufacturing?

Barcodes play a crucial role in the manufacturing industry, enabling businesses to automate various processes and track their products efficiently. Here are a few key applications of barcodes in manufacturing:

- Inventory Management: Barcodes simplify inventory management by providing accurate and real-time data on stock levels, ensuring that the right products are available when needed. Each product can be assigned a unique barcode, making it easy to track its movement within the production facility.

- Quality Control: By incorporating barcodes into quality control processes, manufacturers can accurately monitor and record information about each product’s specifications, manufacturing date, and batch number. This helps identify and rectify any defects or issues promptly, ensuring consistent product quality.

- Traceability: Barcodes facilitate product traceability throughout the manufacturing process, from raw materials to the finished product. This allows manufacturers to track and verify the origin, components, and manufacturing history of each item, ensuring compliance with regulatory standards.

- Production Tracking: Barcodes enable manufacturers to track the progress of products through each stage of the production process. By scanning barcodes at various checkpoints, businesses can monitor production rates, identify bottlenecks, and optimise workflow.

How to Setup a Barcode System for Manufacturing?

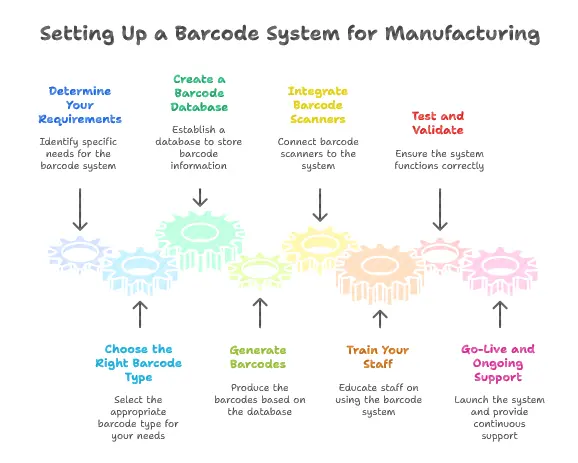

Implementing a barcode system in your manufacturing unit involves several key steps. Let’s explore them:

- Determine Your Requirements

Identify the specific areas in your manufacturing process that would benefit from barcode implementation. Whether it’s inventory management, production tracking, or quality control, understanding your requirements will help you choose the right barcode system.

- Choose the Right Barcode Type

Select a barcode symbology that suits your needs. Common types include Code 39, Code 128, and QR codes. Consider factors such as data capacity, readability, and compatibility with existing systems.

- Create a Barcode Database

Establish a centralised database to store and manage barcode-related information. This database should link each barcode to relevant product data, such as descriptions, pricing, and inventory levels.

- Generate Barcodes

Utilise barcode generation software or online tools to create unique barcodes for each product or item. Ensure that the barcodes are clear, scannable, and printed in the appropriate size and format.

- Integrate Barcode Scanners

Integrate barcode scanners into your manufacturing processes, ensuring compatibility with your database and other software systems. Barcode scanners can be handheld devices or fixed scanners installed at various checkpoints.

- Train Your Staff

Provide comprehensive training to your staff, ensuring they understand the barcode system’s functionalities and how to effectively use barcode scanners to maximise efficiency.

- Test and Validate

Conduct rigorous testing to ensure that the barcode system is functioning accurately and reliably. This includes scanning barcodes at various stages of the manufacturing process to verify data accuracy and system responsiveness.

- Go-Live and Ongoing Support

Once the barcode system is successfully implemented, provide ongoing technical support and maintenance to address any issues or further customization requirements.

According to recent reports by the Confederation of Indian Industry (CII), over 70% of manufacturing units in India have implemented barcode systems to streamline operations.

How to Implement a Barcode System in Manufacturing? – The Qodenext Process

Qodenext offers a superior and innovative approach to implementing barcode systems in manufacturing. Here’s how the Qodenext process stands out:

Step 1: Comprehensive Assessment

Qodenext experts perform an in-depth assessment of your manufacturing processes, aiming to identify not only the areas that could benefit from barcode implementation but also potential bottlenecks or inefficiencies. This holistic approach ensures that the barcode system integration addresses your unique requirements and maximises overall productivity.

Step 2: Tailored Solutions

Qodenext understands that each manufacturing unit is different. They provide customised barcode solutions that align with your existing infrastructure, minimising disruptions and optimising the integration process. Qodenext works closely with your team to develop a barcode system that seamlessly integrates with your manufacturing processes and enhances efficiency.

Step 3: Advanced Integration Capabilities

Qodenext excels in integrating barcode systems with web applications, enabling real-time data capture and synchronisation. This allows for seamless coordination between barcode scanners and your existing web-based software systems, enhancing data accuracy and enabling efficient data analysis.

Step 4: User-Friendly Interface

Qodenext prioritises user-friendliness, ensuring that the barcode system is intuitive and easy to use for your staff. They provide comprehensive training and support, empowering your team to leverage the barcode system’s full potential and achieve maximum productivity gains.

Step 5: Continuous Improvement

Qodenext’s commitment doesn’t end with the implementation. They offer ongoing support, maintenance, and regular system updates to address any evolving needs or technological advancements. Qodenext continuously works towards optimising the barcode system’s performance and adapting it to your changing manufacturing requirements.

Wrapping Up

Implementing a barcode system in your manufacturing unit can revolutionise your operations, improving accuracy, efficiency, and traceability. By following the step-by-step process outlined in this article and embracing the Qodenext barcode implementation process, you can seamlessly integrate barcode technology into your manufacturing processes. Qodenext’s superior and innovative approach ensures a customised solution that maximises productivity and streamlines your manufacturing operations. Contact Qodenext to get a customized barcode system for your manufacturing unit today.

FAQs: How to Implement Barcode System in Manufacturing

1. Are barcodes only used in large-scale manufacturing units?

No, barcodes are used in manufacturing units of all sizes. From small-scale operations to large enterprises, barcodes offer benefits in terms of inventory management, quality control, and production tracking.

2. Can I use barcode scanners with my existing software systems?

Yes, barcode scanners can be integrated with your existing software systems. Barcode scanning technology is compatible with various software applications, allowing for seamless data capture and synchronisation.

3. Is barcode implementation a costly process?

Barcode implementation can vary in cost depending on the scale and complexity of your manufacturing operations. However, the benefits outweigh the initial investment, as barcodes streamline processes, reduce errors, and enhance overall efficiency.

4. Can I print my own barcodes?

Yes, you can print your own barcodes using barcode generation software or online tools. These tools allow you to create clear and scannable barcodes, customised to your product specifications.

5. What is a barcode system in manufacturing?

A barcode system in manufacturing is a digital tracking method that uses machine-readable codes to identify products, materials, and processes. It helps manufacturers automate data entry, reduce human error, and improve traceability and inventory management across the production line.

6. How does a barcode system improve manufacturing efficiency?

A barcode system improves efficiency by automating inventory tracking, production monitoring, and quality checks. It reduces manual paperwork, speeds up data collection, and ensures accurate product information is available in real time.

7. What are the main components required to set up a barcode system?

The main components include barcode labels, barcode scanners, barcode generation software, and a central database to store and manage product information. Integration with ERP or inventory systems enhances real-time data access and workflow automation.

8. Can a barcode system be used for inventory and warehouse management?

Yes, a barcode system is ideal for inventory and warehouse management. It enables manufacturers to track stock movement, monitor product quantities, prevent stockouts, and maintain accurate records of incoming and outgoing goods.

9. How much does it cost to implement a barcode system in a manufacturing unit?

The cost varies depending on the system’s complexity, number of products, and software integration needs. Small setups can start from ₹50,000–₹1,00,000, while enterprise-level barcode systems with automation can cost several lakhs. However, the long-term ROI is high due to efficiency gains.

10. How do I choose the right barcode system provider for manufacturing?

Choose a provider that offers end-to-end solutions, including system assessment, customized integration, and technical support. Companies like Qodenext specialize in scalable barcode solutions for manufacturing, ensuring seamless integration with your existing operations.