Having obsolete and unsold inventory or slow-moving products is quite a hassle for your warehouses. While hoarding them is not an option- you can liquidate them.

That’s what dead inventory liquidation is all about. Holding onto dead inventory can drain resources, tie up valuable storage space, and hurt cash flow. So, implement effective strategies that can recapture the lost value, improve financial health, and make room for profitable products.

This guide will walk through the best practices for liquidating dead inventory effectively.

But first, let’s see the fundamental dead inventory.

What is Dead Inventory?

Have you ever walked into a warehouse or checked your inventory and discovered items that haven’t been touched in ages? Those forgotten, dust-covered products are known as dead inventory.

When there is inventory that has not sold for a long time and is unlikely to sell in the future, it is termed“dead inventory”. It occupies storage space while also restricting capital. Not to mention, it fails to generate revenue.

What you need is dead inventory liquidation. But why is that important? Let’s understand that first.

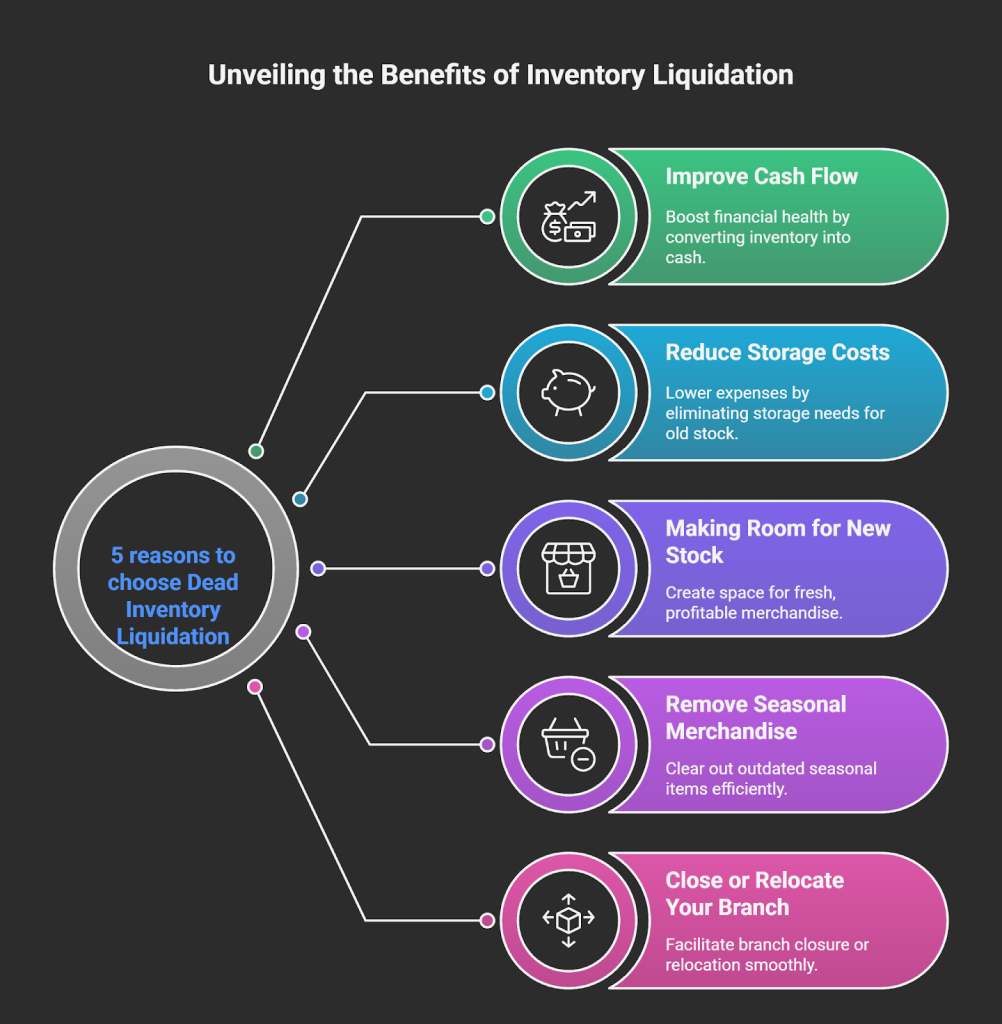

5 Reasons to Choose Dead Inventory Liquidation

There are various reasons why companies choose to liquidate their inventory:

1. Improve Cash Flow

Having excess inventory blocks significant capital that you could use in other aspects of the business. By selling outdated or low inventory, you can ensure better cash flow.

Businesses usually sell off their outdated inventory to use the cash and invest in operational needs or new items.

Another way to ensure better cash flow is by increasing the number of payment methods. Customers find it easier and preferable to work with companies and brands that offer multiple and flexible payment options.

Also, with AI and other tools, companies can automate the payment and invoice generation methods.

2. Reduce Storage Costs

Excess inventory takes up storage that can be better used for other purposes. Liquidating stock frees up space, making the most use of the space. With proper storage strategies, you can ensure a well-organised and clutter-free inventory.

3. Making Room for New Stock

Introducing new products means retail companies need to make space for them in thoier shelves and warheouses. And what are the best ways to make space?

Liquidating their old inventory.

With dead inventory liquidation, stores can remove their old merchandise to make room for the new ones. Retailers can make room for the newest products by removing those that aren’t selling out,

This helps them to keep along with the trends and also gain customer trust.So, the next time you see a clearance sale, remember—it’s also about dead inventory liquidation and not just a great deal!

4. Remove Seasonal Merchandise

Retailers dealing with seasonal products can opt for excess inventory liquidation in India. Liquidation allows quick clearing of the seasonal stock.

Retailers must track sales data and monitor trends so they can make informed decisions about seasonal inventories. This helps you to determine the best times to hold sales or have promotions.

Also, consider offering timed discounts with your inventory liquidation services. Bundle discounts or periodic reductions greatly help in liquid inventory management, making it easier to sell out excess stock.

5. Close or Relocate Your Branch

When a retail company closes or relocates its store, they must clear out the remaining inventory from the location. Liquidation is the best practice in such situations.

By implementing dead inventory liquidation, businesses can move all leftover goods from the location. Selling off these items turns them into cash, which then can help the business fund some of its expenditures.

This way, businesses can recover value from these items, avoid product wastage, and ensure a seamless transition to the new location.

But how to liquidate inventory? We are here to help you out.

4 Inventory Liquidation Strategies

Dead inventory liquidation strategies help you to understand the causes behind the dead stock in your business. With these strategies, you can prevent dead stock thus maintaining profitability by restricting your storage costs:

1. Improved Demand Forecasting

The first step to preventing dead stock is improving your demand forecasting. You can enhance your forecasting accuracy by analyzing historical product data, sales patterns, and market trends.

Optimised demand forecasting provides greater control over inventory, helping you make informed decisions. Inventory software systems can also avoid over-purchasing and reduce investment in slow-moving products that may eventually become dead stock.

2. Streamlining Stock Keeping Units (SKUs)

Streamlining your SKUs is a process of stock rationalisation where you measure the profitability of the products manufactured or stocked. Using production, purchase, inventory storage cost metrics and historical sales data, you can know if you need to keep an SKU or discontinue it, or retain it with modifications.

All these factors help you decide whether these SKUs are helping or harming your business. Streamlining inventory SKUs lowers operational costs mitigating the risk of dead stock.

3.Optimize Order Volumes

Consider choosing small order quantities or reducing your production runs, especially crucial when you are dealing with trendy or seasonal items that can have a rapid decline in customer demand.

Don’t worry, there’s a solution.

A Just-in-time inventor. With this system, you can accept orders in small quantities more frequently, eliminating overproduction or over-ordering. You can avoid a buildup of unsaleable stock that is destined to become dead stock.

4. Implementing Inventory Optimization Software

Inventory optimisation software is the best defence against dead inventory liquidation.

No inventory management optimisation means you will have dead stock in your warehouse. It remains forgotten and takes up valuable space. With inventory management software, you can stop this accumulation of dead stock in the first place.

Inventory software solutions allow you to track, monitor, and have visibility of your inventory in real-time. You can maintain continuous turnover, which prevents stock out, spoilage, or dead inventory.

While these liquidation strategies can get you started on managing your dead inventory, how can you manage it? Here are some management tips.

Dead Stock Inventory Management

Due to overstocking, you need to liquidate inventory meaning, clear out the excess stock. This is one way to prevent dead stock. At the core of this lies inventory software and solutions that help achieve timely inventory control.

To know if your inventory has “dead stock”, you need to conduct an analysis, as follows:

Dead Stock Analysis

Deadstock analysis helps determine the value and location of unsold items. You can achieve this by live tracking and monitoring inventory levels across the business.

The best way to manage dead stock inventory is to ensure it’s not there at all. automated inventory management helps manage dead inventory liquidation but also stops its accumulation.

Inventory management software helps manage purchase orders and tracks the orders, helping manage returns. By tracking your inventory, you can see where it’s across your supply chain. Also, the software reporting and analytics capabilities improve demand forecasting, reducing the risk of acquiring dead stock.

Conclusion

Effective dead inventory liquidation is essential for businesses to maintain cash flow, reduce storage costs, and make room for new, profitable products. By implementing proper liquidation strategies, such as demand forecasting, optimizing SKUs, and using inventory management software, companies can prevent dead stock accumulation and ensure their resources are used efficiently.

With experts from Qodenext and its supply chain solutions, businesses can recover value from slow-moving products, streamline operations, and foster continued growth, ultimately enhancing both profitability and inventory management practices.FAQs: The 2024 Blueprint for Effective Dead Inventory Liquidation

FAQs: The 2024 Blueprint for Effective Dead Inventory Liquidation

1. What is inventory liquidation?

Inventory liquidation is the process of selling excess, obsolete, or surplus stock—often at discounted prices—to free up space, recover costs, and improve cash flow.

2. Why do businesses choose inventory liquidation?

Businesses liquidate inventory to reduce storage costs, minimize losses from unsold goods, clear outdated products, and generate immediate cash.

3. What types of products are liquidated?

Any type of product can be liquidated, including electronics, apparel, furniture, FMCG goods, seasonal items, and returned merchandise.

4. How is inventory liquidation different from regular sales?

Regular sales aim at maximizing profit, while liquidation sales focus on quickly clearing stock—even if it means selling at a reduced margin or loss.

5. Who buys liquidated inventory?

Buyers may include wholesalers, discount retailers, resellers, e-commerce sellers, liquidation companies, and end consumers seeking bargains.

6. What are the common methods of liquidation?

Businesses use methods such as liquidation companies, auctions, bulk buyers, online marketplaces, or clearance sales to liquidate stock.

7. Can liquidation help improve cash flow?

Yes, liquidation helps convert idle inventory into cash quickly, improving liquidity and enabling businesses to reinvest in profitable products.

8. Is liquidation suitable for small businesses?

Absolutely. Small businesses benefit by freeing up space, reducing storage costs, and avoiding further losses on unsold goods.

9. Are there risks in inventory liquidation?

Yes. Risks include lower profit margins, brand devaluation if products are sold cheaply, and potential conflicts with regular distributors or retailers.